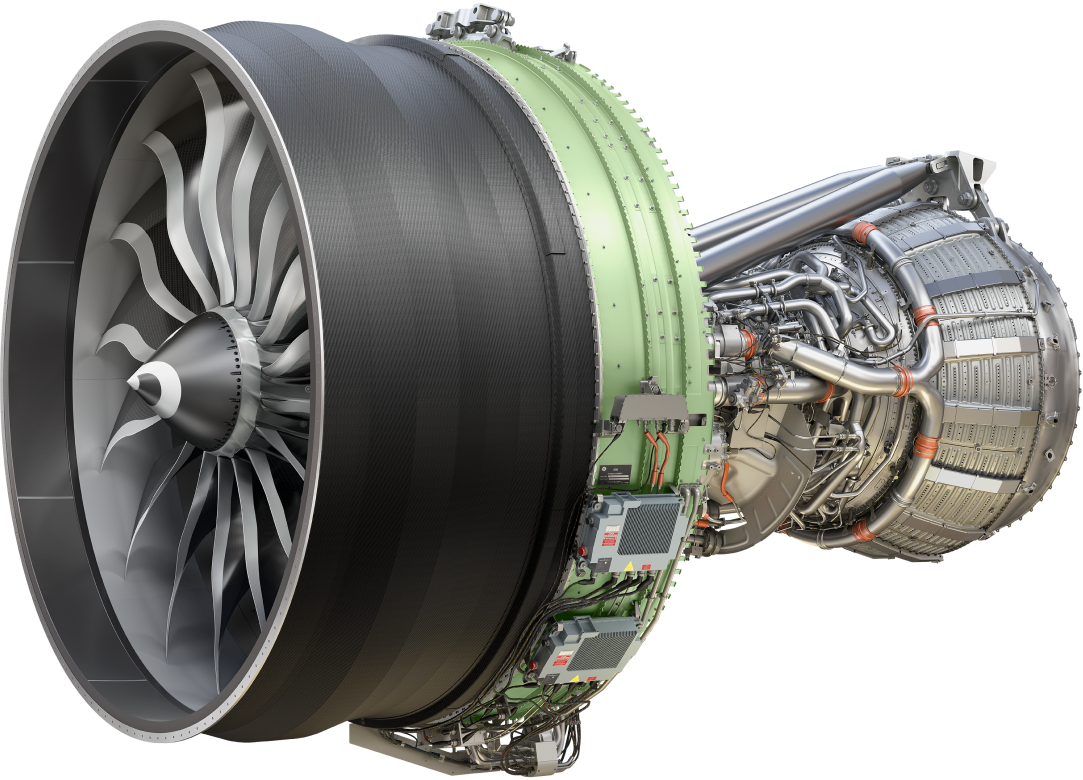

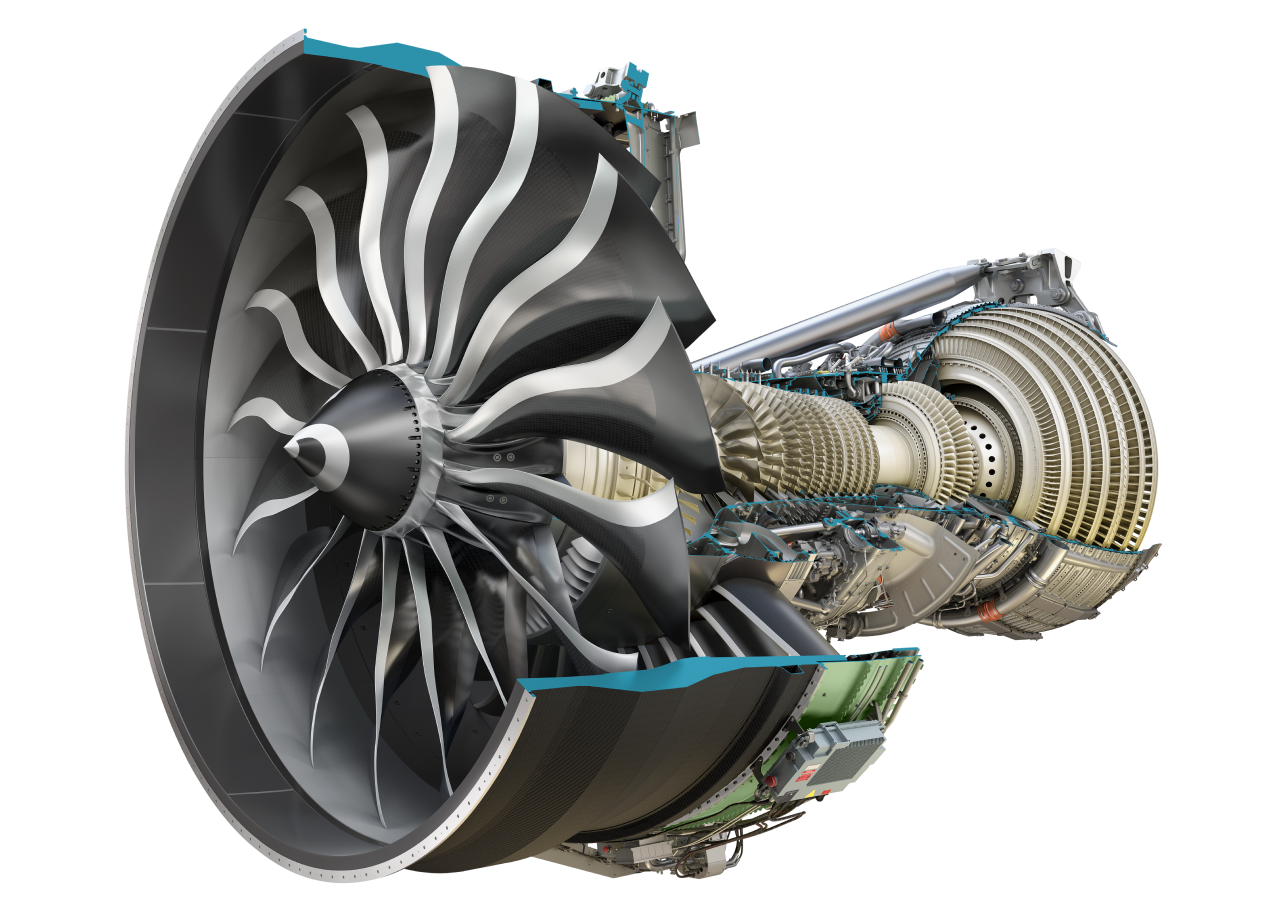

The GE9X is the largest and most powerful commercial aircraft engine ever built, incorporating advanced technologies that enable more efficient, quieter flight with fewer emissions. Designed specifically for the new twin-engine Boeing 777X family, the GE9X is the most fuel-efficient engine in its class, delivering unmatched reliability and performance.

The highest thrust of any commercial jet engine — equivalent 597.396 kN

Purpose built for the Boeing 777X family of aircraft

The GE9X represents a multi-generational technology development chain, supported by millions of hours of field experience. We have pulled learnings from other engines, including the GE90 and GEnx, to enable a more efficient, more reliable, quieter engine with lower emissions.

GE9X

Combined with the Boeing 777X, the GE9X delivers the best airline economics and profitability via reduced fuel consumption, emissions, and associated costs, and lowest environmental impact.

World-leading

New technology and materials keep us at the forefront

Fuel consumption improvement

Provides a 5% specific fuel consumption improvement versus any twin-aisle engine available.

Fuel consumption improvement

Delivers up to 10% specific fuel consumption improvements versus the GE90-115B engine.

Composite fan blades

Fourth-generation composite fan blades maximize airflow and minimize drag.

Bypass ratio

Achieves an approximate 10:1 bypass ratio plus a 60:1 overall pressure ratio and margin to stage 5 noise limits.

Engineered with the environment in mind

Environmental performance

The GE9X features the same world-class reliability as the GE90-115B, with noise and NOx emissions well below anticipated regulation standards.

n/a

The GE9X engine produces half the NOx of any engine in its class at a level that is less than half of current requirements.

Less SFC: Annual fuel savings due to the GE9X having 10% less SFC vs GE90 is approximately 3,000 metric tons of fuel, which is roughly 9,500 metric tons of CO2 and roughly 2,060 cars removed from the road.

Lower emissions: All emission values at or below current regulatory requirements. 50% lower emissions (CO, Particulate, NOx).

Turbofan engine: Per pound of static thrust produced, the GE9X is the quietest turbofan engine GE Aerospace has ever produced, and is designed to meet current and anticipated next level of noise certification standards on the B777X Family.

There is no substitute that can achieve the combination of size, power and fuel efficiency of the GE9X. This engine will deliver unsurpassed value and reliability to our airline customers.

Tested, Validated, Certified

GE9X received FAA certification in September 2020

The GE9X has been through the most rigorous testing program of any GE commercial aircraft engine in history. The engine accumulated close to 5,000 hours and 8,000 cycles of ground testing plus 72 test flights totaling more than 400 hours on GE’s 747 Flying Test Bed.

Ice test

The GE9X during the third phase testing at our test facility in Evendale, Ohio