RACER Comes to Life: The Hybrid Helicopter-Plane RACER Takes Shape

June 01, 2022 | by Yari Bovalino

Efficient, super-fast and cutting edge. The RACER, with its hybrid helicopter-plane design, has begun to take shape at the Airbus Helicopters assembly plant at Donauwörth, in Bavaria. It’s recently been moved to the company's headquarters in Marignane, southern France, where the structure will be completed and fitted with an engine and a state-of-the-art transmission system.

With cruise-speeds of up to 220 knots (400 km/h), RACER will have a range of more than 400 nautical miles.

“The aim is to demonstrate the capabilities of the RACER in missions where speed is crucial such as for passenger transport, emergency medical and health services, and search and rescue. Of course, the purpose of the demonstrator is also to demonstrate the reduction in emissions (CO2, NOx and noise) and the cost-benefit ratio”, says Julien Guitton, RACER Program Leader at Airbus Helicopters.

The project, born under the aegis of Clean Sky 2, is the largest public-private R&D partnership program with the EU. And preparatin is now underway for its next phase: Clean Aviation. Right from the start, the RACER has proven to be a radical advance for the specialists in accessory gearboxes and power transmissions at Avio Aero. In fact, the Main Gearbox (MGB) that connects the engine to the helicopter blades were designed and constructed in tight collaboration with Airbus Helicopter.

"This co-development project was carried out in a spirit of collaboration and mutual support, endeavoring at every stage to harness and bring together the best practices and expertise of both teams," said Marinella Marconi, RACER Technical Leader at Avio Aero. "We are now entering the busy production stage for the MGB, with on-going exchanges between our teams and our suppliers."

The lateral gearboxes (LGBs) can create 1MW of power and represent a cutting-edge product exclusively developed for the RACER. As Andrea Demarin, Racer Program Manager at Avio Aero, explained: "We finished assembling the first lateral gearbox module - the one on the left - last month. This will now be subjected to flight clearance tests, required for the aircraft to be authorized for flight. These flight clearance tests will be carried out on special purpose-built benches that have been set up in the hangars at the Sangone Experimental Center."

This is the culmination of many months of work in design, development and finally industrial production, conducted together with Airbus Helicopters and with the help of other SMEs. "Our partnership, our integrated team, has really proved to be a unique model of collaboration in a highly competitive environment” adds Guitton. “These efforts are now bearing fruit, with practical results that are now being tested and will soon be in flight."

Moreover, the RACER will also benefit from some innovative solutions developed for the Catalyst engine. In fact, the advanced, all made-in-Europe, turboprop embeds new Clean Sky2 technologies and is currently undergoing flight tests. Among these innovations there is the ACOC (air cooler oil cooler) heat exchanger made with additive technology. A similar component has been designed and manufactured for the LGBs of the RACER demonstrator.

“Manufacturing the ACOC with additive technology has allowed us to design a highly integrated and compact lubrication and cooling system: this can fit in the space between the housing of the LGB and the aircraft nacelle, and integrates functions of the oil system in addition to heat exchange. It’s a single component integrating multiple functions," Demarin said.

The Avio Aero laboratory, in partnership with the Politecnico (TAL), studied these solutions with DMLM (direct metal laser melting) technology, the same with which the Catalyst components are 3D printed (some developed in the same way at the laboratory on the campus of the University of Turin). “We applied what we learned from the Catalyst to resolve the design, manufacturing and flight clearance issues related to the Racer," says Demarin.

Other European teams also played an important role in the development of the RACER, as Marconi explains, including the engineering team Avio Aero Polska.

The RACER will now be tested for the Clean Sky2 program, after which it will be deployed according to its “multi-role” nature in aerial applications where speed makes the difference. "We want to continue with a technology-driven approach, in order to stimulate the market of civil aviation and attract potential customers," Guitton said. "The flight test campaign will help us define the details and optimize the results that will help us shape the hybrid helicopter of the future."

With cruise-speeds of up to 220 knots (400 km/h), RACER will have a range of more than 400 nautical miles.

“The aim is to demonstrate the capabilities of the RACER in missions where speed is crucial such as for passenger transport, emergency medical and health services, and search and rescue. Of course, the purpose of the demonstrator is also to demonstrate the reduction in emissions (CO2, NOx and noise) and the cost-benefit ratio”, says Julien Guitton, RACER Program Leader at Airbus Helicopters.

The project, born under the aegis of Clean Sky 2, is the largest public-private R&D partnership program with the EU. And preparatin is now underway for its next phase: Clean Aviation. Right from the start, the RACER has proven to be a radical advance for the specialists in accessory gearboxes and power transmissions at Avio Aero. In fact, the Main Gearbox (MGB) that connects the engine to the helicopter blades were designed and constructed in tight collaboration with Airbus Helicopter.

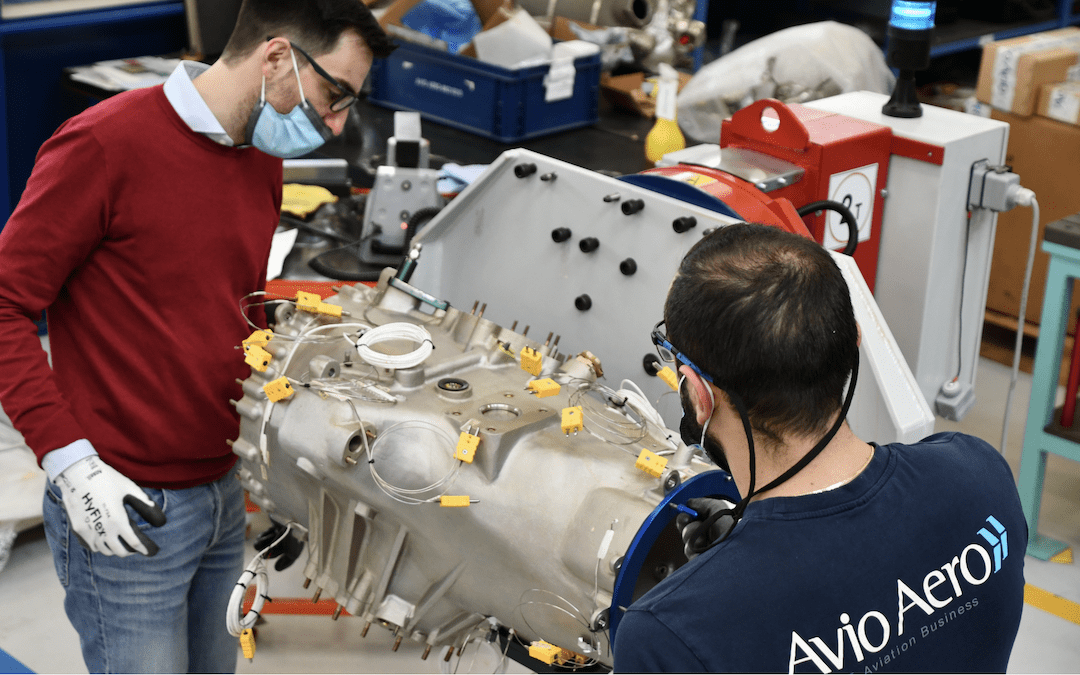

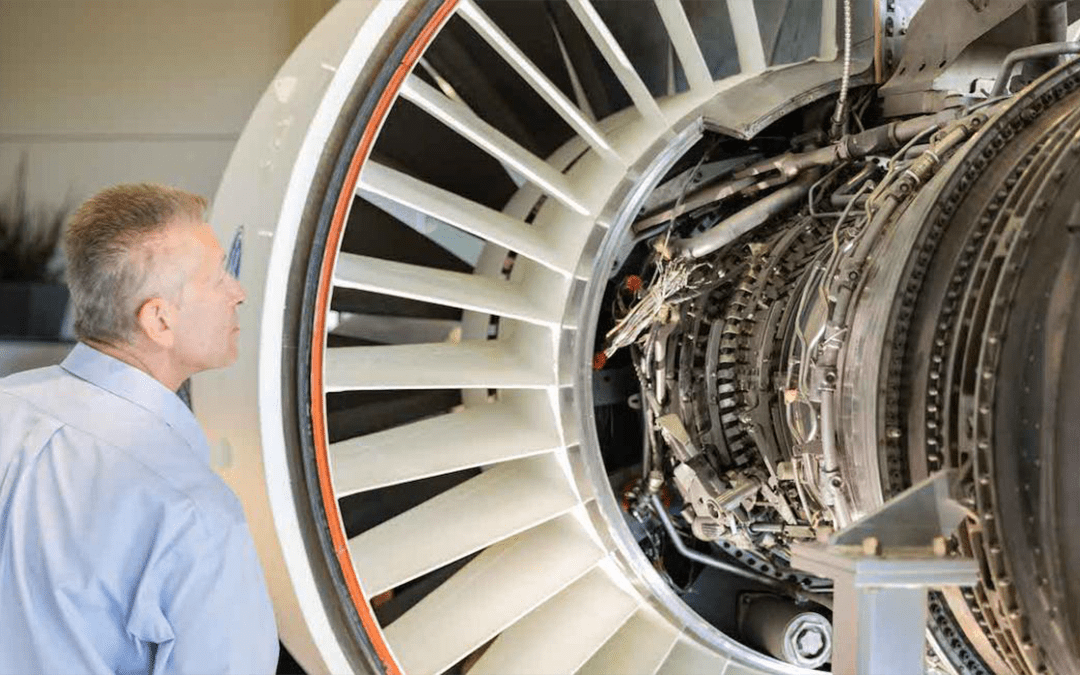

Above: RACER in the assembly at Airbus Helicopters plant. ©2022 Airbus Top: Avio Aero employees during final assembly of the lateral gearboxes at the Rivalta di Torino plant.

Above: RACER in the assembly at Airbus Helicopters plant. ©2022 Airbus Top: Avio Aero employees during final assembly of the lateral gearboxes at the Rivalta di Torino plant.

"This co-development project was carried out in a spirit of collaboration and mutual support, endeavoring at every stage to harness and bring together the best practices and expertise of both teams," said Marinella Marconi, RACER Technical Leader at Avio Aero. "We are now entering the busy production stage for the MGB, with on-going exchanges between our teams and our suppliers."

The lateral gearboxes (LGBs) can create 1MW of power and represent a cutting-edge product exclusively developed for the RACER. As Andrea Demarin, Racer Program Manager at Avio Aero, explained: "We finished assembling the first lateral gearbox module - the one on the left - last month. This will now be subjected to flight clearance tests, required for the aircraft to be authorized for flight. These flight clearance tests will be carried out on special purpose-built benches that have been set up in the hangars at the Sangone Experimental Center."

This is the culmination of many months of work in design, development and finally industrial production, conducted together with Airbus Helicopters and with the help of other SMEs. "Our partnership, our integrated team, has really proved to be a unique model of collaboration in a highly competitive environment” adds Guitton. “These efforts are now bearing fruit, with practical results that are now being tested and will soon be in flight."

Moreover, the RACER will also benefit from some innovative solutions developed for the Catalyst engine. In fact, the advanced, all made-in-Europe, turboprop embeds new Clean Sky2 technologies and is currently undergoing flight tests. Among these innovations there is the ACOC (air cooler oil cooler) heat exchanger made with additive technology. A similar component has been designed and manufactured for the LGBs of the RACER demonstrator.

“Manufacturing the ACOC with additive technology has allowed us to design a highly integrated and compact lubrication and cooling system: this can fit in the space between the housing of the LGB and the aircraft nacelle, and integrates functions of the oil system in addition to heat exchange. It’s a single component integrating multiple functions," Demarin said.

The Avio Aero team during final assembly.

The Avio Aero team during final assembly.

The Avio Aero laboratory, in partnership with the Politecnico (TAL), studied these solutions with DMLM (direct metal laser melting) technology, the same with which the Catalyst components are 3D printed (some developed in the same way at the laboratory on the campus of the University of Turin). “We applied what we learned from the Catalyst to resolve the design, manufacturing and flight clearance issues related to the Racer," says Demarin.

Other European teams also played an important role in the development of the RACER, as Marconi explains, including the engineering team Avio Aero Polska.

The RACER will now be tested for the Clean Sky2 program, after which it will be deployed according to its “multi-role” nature in aerial applications where speed makes the difference. "We want to continue with a technology-driven approach, in order to stimulate the market of civil aviation and attract potential customers," Guitton said. "The flight test campaign will help us define the details and optimize the results that will help us shape the hybrid helicopter of the future."