GE Aerospace Inspection Solutions Team ‘Making Waves’ with Enhanced Safety and Quality

April 25, 2024 | by Todd Alhart

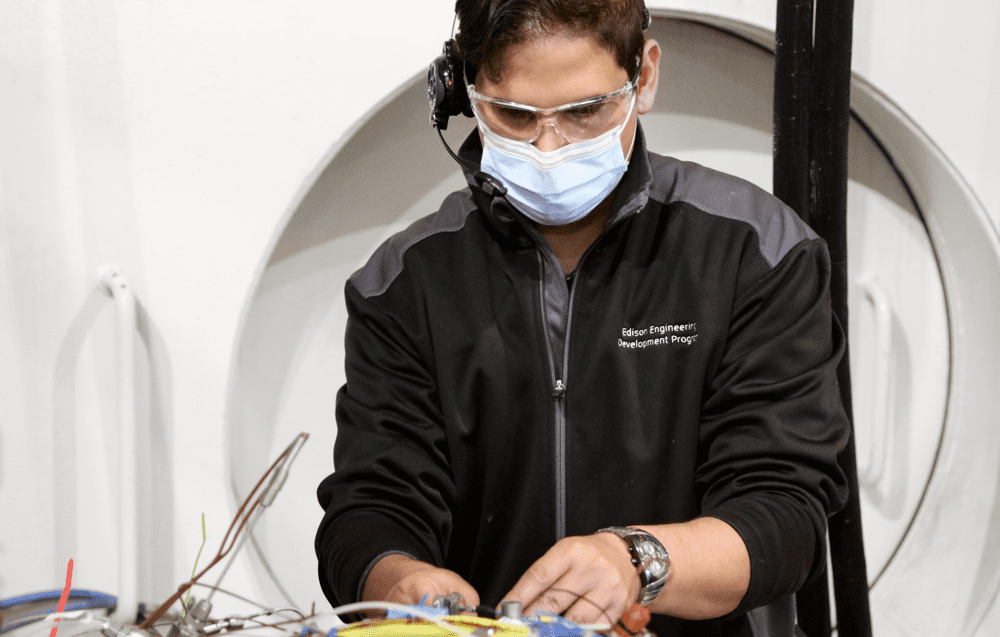

An expertly trained diagnostician carefully moves the ultrasound probe, looking to figure out what’s inside. But this specialist is not in a doctor’s office conducting a medical exam. She’s leaning over an ultrasonic immersion tank filled with water at an aircraft engine inspection development facility, and her “patient” is a high-performance component for a jet engine that powers a commercial airplane capable of carrying 250 passengers more than 8,000 miles.

When it comes to addressing safety in the skies, aerospace inspection engineers are a lot like doctors checking the health of patients. Just as a doctor might look for a cancerous mass or a blockage in an artery with an image scan, aerospace engineers look for minuscule anomalies in metal or ceramic material that might compromise a part. They create and perform inspection processes to make sure parts are healthy. When they see an irregularity, they want to root it out before a larger problem arises. That’s what Anjani Schrad and the team at GE Aerospace’s Aerospace Inspection Solutions (AIS), in Springdale, Ohio, are committed to doing every day.

Ultrasound and other inspection methods give us an extra set of eyes and ears and provide additional context about materials that otherwise would not be possible. “Dolphins and bats use frequencies outside the range of human hearing to ‘see’ food and avoid obstacles,” Schrad says. “We’re using them to see features inside engine components.” It’s all part of a new suite of advanced imaging technologies and methods being developed to address safety and quality while also driving a future of faster, more efficient, and more sensitive aircraft engine inspections.

In addition to ultrasound, GE Aerospace engineers use X-ray, computed tomography, flash thermography, eddy current testing, fluorescent penetrant inspection, and dimensional metrology to inspect engine components. It all depends on what can best interrogate a given material or part, and these modalities are commonly used in combination to help the engineer best determine the serviceability of the asset. Image-processing algorithms are developed for each inspection method to improve the accuracy and consistency of data interpretation.

AIS: Our ‘Early Troubleshooters’ for Enhanced Safety

In 2016, a failure of a critical rotating engine component resulted in an aborted takeoff in Chicago and an evacuation of the aircraft during which several passengers were injured.

The investigation revealed that the incident was caused by a defect known as a “dirty white spot,” an anomaly that can arise in alloy remelting. Materials experts all across the aviation industry and academia have since been working to prevent dirty white spots from entering the material stream, while inspection experts have been inventing new techniques to detect this specific type of defect. One of those involves enhanced ultrasound imaging.

Using a version of enhanced ultrasonic inspection in a separate case, GE Aerospace engineers identified and self-reported a previously undetectable defect in one of its jet engine components. The team communicated its findings to the Federal Aviation Administration, proactively issued service bulletins, and worked with its maintenance, repair, and overhaul (MRO) network to address the matter. To date, thousands of parts have been inspected in the field using this advanced method.

Ever wondered why ultrasound technicians squirt gel on the outside of an ultrasound probe before scanning a patient? It’s because the air interferes with the sound waves being transmitted to get a clear image inside the body. For industrial inspection of engine parts, the GE Aerospace AIS team submerges the part in a tank of water to prevent air from interfering with sound waves.

Currently, the AIS team is working with the regulatory agencies through the Aerospace Industry Association and collaborating with other jet engine manufacturers and stakeholders to further improve enhanced ultrasonic inspection techniques. “This is why we do what we do,” Schrad says. “If a potential issue arises, we want to catch it and take action to remedy it as early as possible, no matter the cost in time and resources.”

Schrad says she’s grateful to be able to work in conjunction with other jet engine makers. “We compete on many levels, but safety is not one of them,” she says. “At the heart of our purpose, the most important thing is the safety of the flying public.”