Test

services

Unique specialized

facilities

Our extensive and unique test facilities and experienced team will meet your most challenging testing needs.

Testing capabilities overview

With over 100 years of aviation product design and testing experience, GE Aerospace has developed comprehensive and flexible testing processes and skills that complement our unique test facilities – all to deliver the results you need the first time and every time. From planning to design, instrumentation, test execution and beyond, let us leverage our experience to deliver results for you.

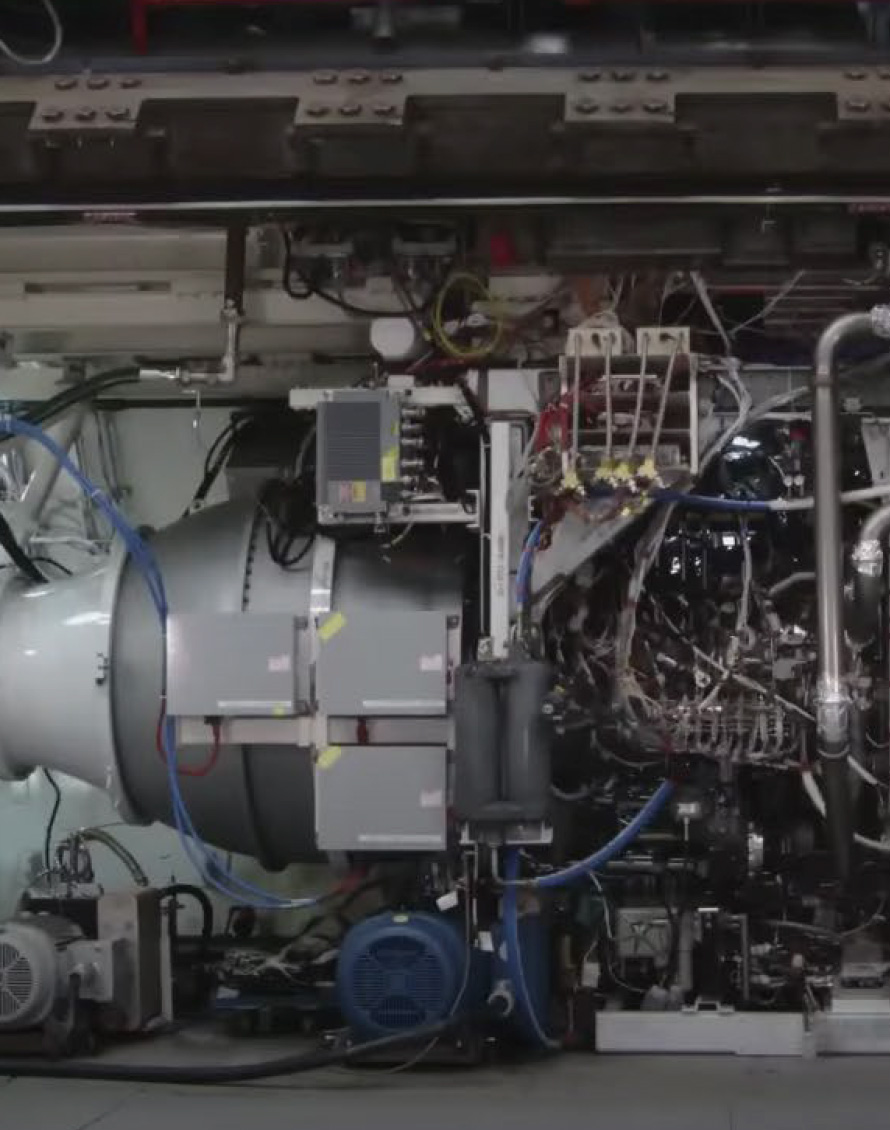

Altitude Test

GE Aerospace has some of the largest and most capable altitude test cells commercially available. Drawing on GE Aerospace’s vast experience in Military and Commercial Engine testing and our extensive support facilities, a wide range of altitude testing is possible. The flexibility in these facilities also allows for testing beyond gas turbine engine tests, including altitude relight performance for combustors, industrial turbocharger component performance mapping, and icing tests.

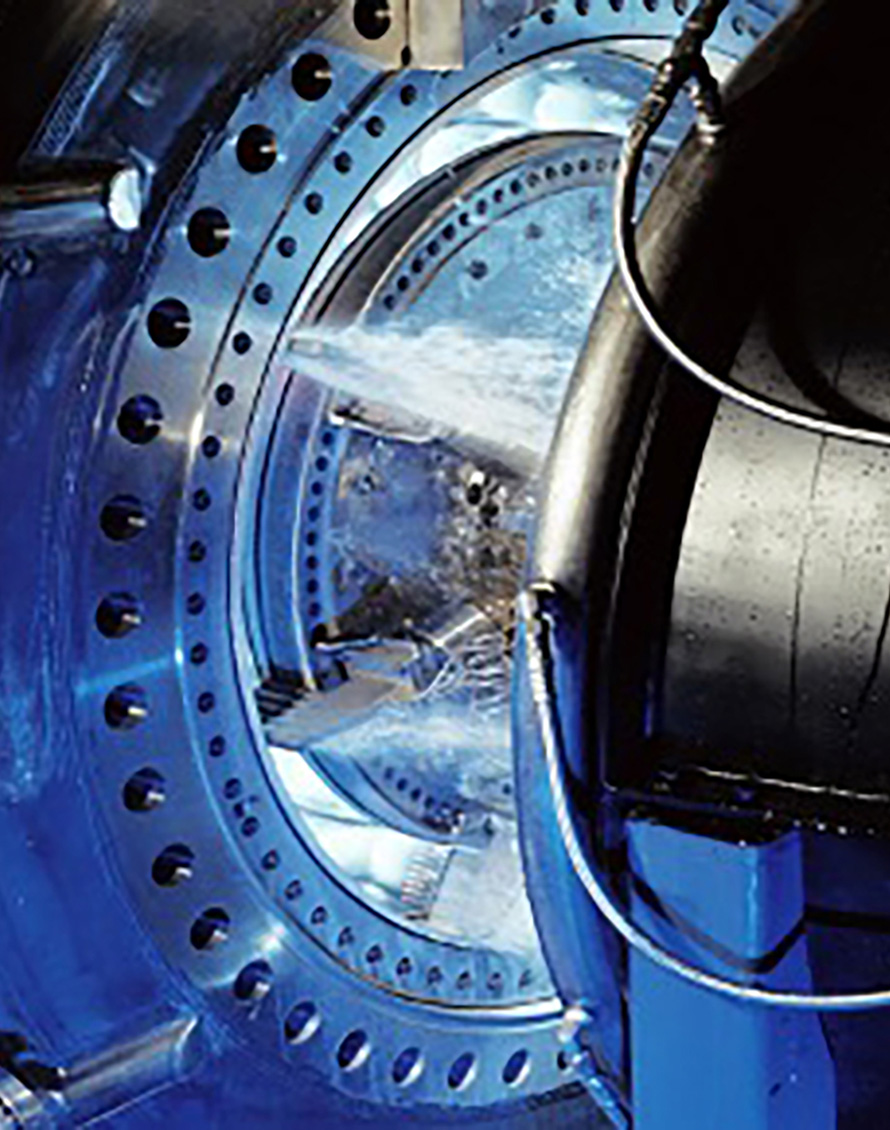

Combustion Test

Our experienced team performs spin testing, including cyclic endurance, bladeout/blade-off, and ingestion testing, and also provides explosives development, high-speed video, and static impact. Our range of facilities includes the largest vacuum chamber for spin testing in the world, capable of testing rotors well beyond the largest turbofan fan blade dimensions.

Icing & Ice Cloud Test

GE Aerospace has extensive and unique test facilities capable of open loop icing and ice cloud testing, supported by a diverse and experienced staff at three locations in North America. Normally used for engineering and certification icing tests for GE Aerospace products, they are also useful for wherever continuous, repeatable icing, and ice cloud conditions are needed.

Turbine Test

Our facilities span the full TRL range and can precisely answer your turbine performance questions. Whether it’s low pressure, high pressure, dual spool (LP/HP), single-stage, or multi-stage, we get the data you need for performance mapping & derivatives, vane clocking sensitivity, secondary flow effects, and more. We can provide an extended range of pressure ratio, temperature ratio, density ratio, and Reynolds numbers.

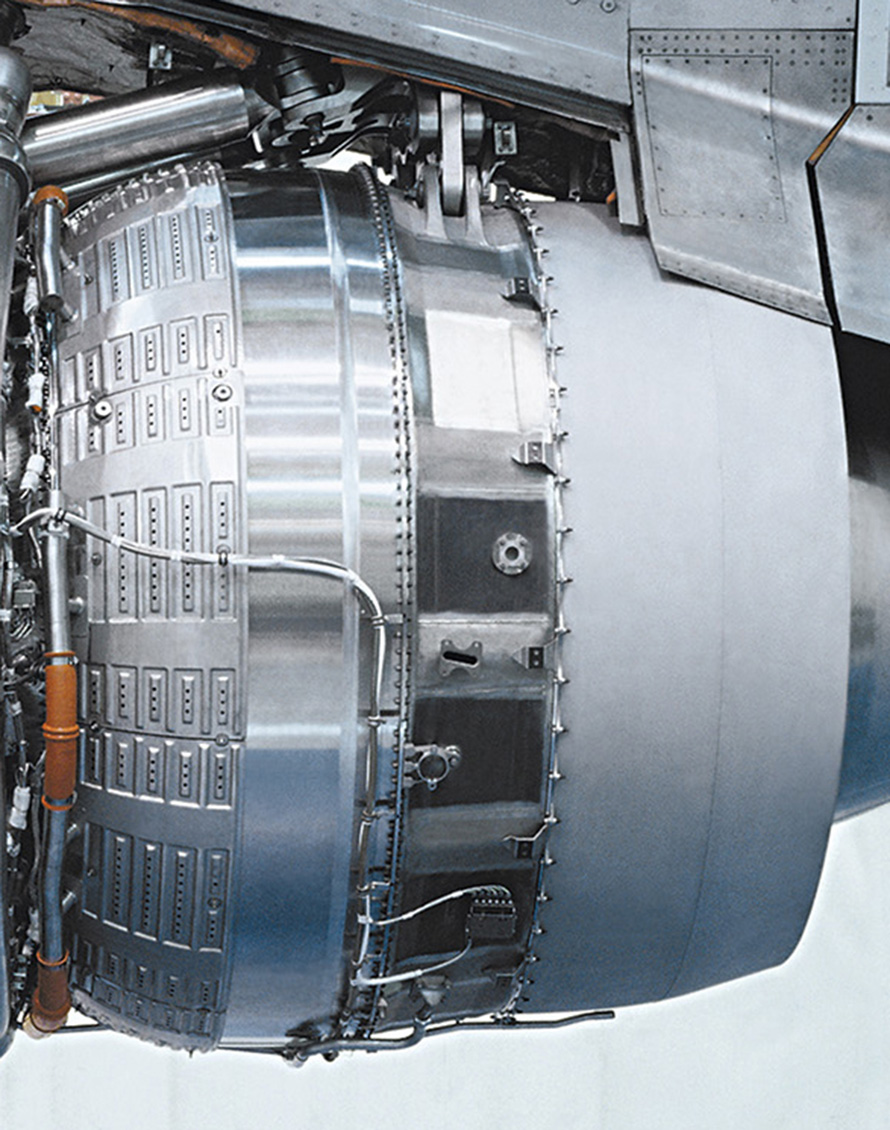

Flight Test Operations

Our current flying test bed, a 747-400, has flown test engines ranging in thrust from 20K to 115K. Specially adapted for engineering tests, a large channel count for steady-state and dynamic measurements is available with on-board data systems, cameras, satellite downlinks, and support systems such as electrical load banks, and conditioned & uninterruptible power. Full ground support is available at the Victorville, CA base with FAA Part 145 Repair Station Certification, as well as access to the R-2508 Complex, the largest flight test airspace in the US. Flight test planning, flight operation, instrumentation design, propulsion and avionics system integration, mechanical design/modification, and flight test line maintenance support are all available.

Rotor Spin Test

Our experienced team performs spin testing, including cyclic endurance, bladeout/blade-off, and ingestion testing, and also provides explosives development, high-speed video, and static impact. Our range of facilities includes the largest vacuum chamber for spin testing in the world, capable of testing rotors well beyond the largest turbofan fan blade dimensions.

Vibration & Structural Test

We provide large scale structural testing, including torque test to failure up to 650,000 lb-ft, tensile/compressive loads up to the 500,000 lbf range, bearing and load calibrations, and automated cyclic testing. For vibration, closed-loop HCF testing is available with shakers up to 24,000 lbf (sinusoidal and random, with shock capabilities), as well as 1D and 3D Laser Doppler Velocimetry with derotator, modal capabilities (on-site or remote), and travelling wave. Large, hooded 5’x5’ shake tables allow for environmental testing from -95 Deg F to 525 Deg F and 10% to 98% humidity control, with full operation of fuel, hydraulic, mechanical, electrical, and digital systems while under vibration test.

Design Consultation

GE Aerospace has a long history of inventing, designing, and delivering test solutions, from test cell design to data systems design, to unique test support equipment and instrumentation design. Our processes are grounded in design practices that capture decades of extensive experience and lessons learned. We can provide design oversight and guidance for your project to realize design intent, and to keep it on time and on budget.

Test Enabling Hardware Design

Unique test requirements drive unique test facilities and unique support hardware. These systems must be highly reliable, safe to operate in demanding conditions, and fault-tolerant. Our experience includes heating/cooling carts, mount systems, auxiliary engine hardware, fuel handling, fire suppression, test rigs, ground handling, and many others. We can design to your exact needs with the benefit of proven design methods and practices.

Testing capabilities overview

GE Aerospace has access to many additional testing facilities and capabilities in a variety of worldwide locations.

If you're looking for additional services, please contact us, and we will show you what is available.