Engines on a mission

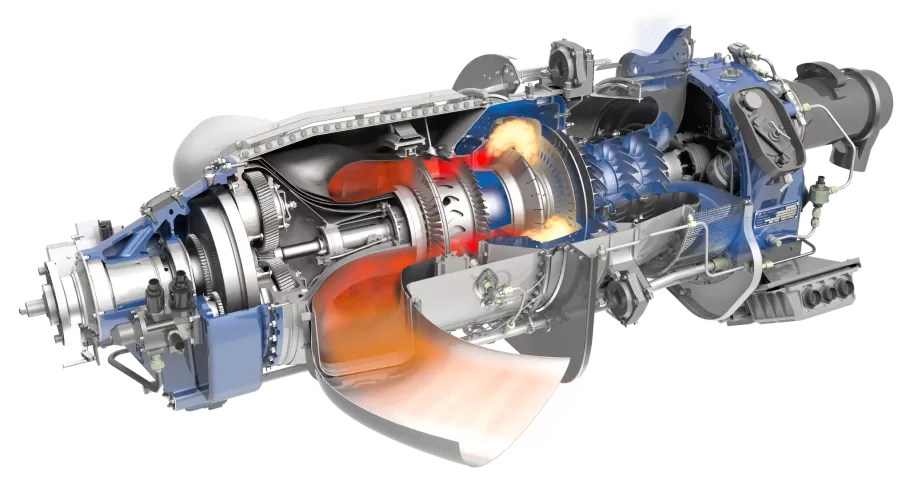

Advanced turboprop

propulsion technology

A Jet-like experience

Maintenance Simplicity

From a pilot’s reduced workload in the cockpit to reduced engine noise in the cabin and industry-leading predictive engine analytics, Airframers, passengers, and crew fly with confidence.

GE Aerospace’s reliability and infused technology mean airlines and charter operators can fly on time and avoid maintenance that may otherwise take engines out of service. H-Series engines have no fuel nozzles and no hot section inspections, easing the burden of additional maintenance.

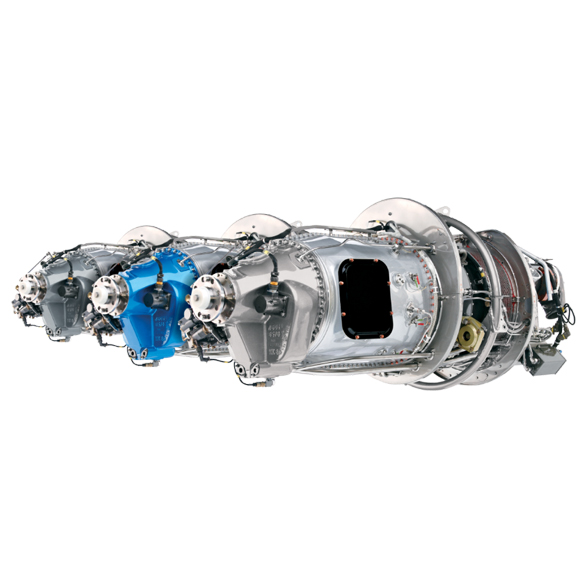

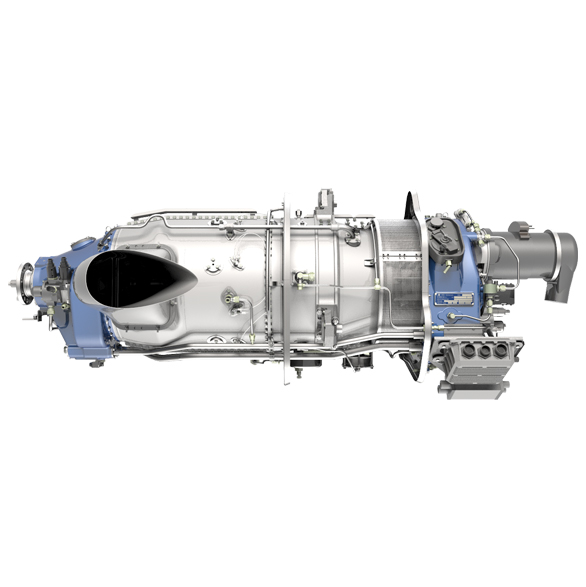

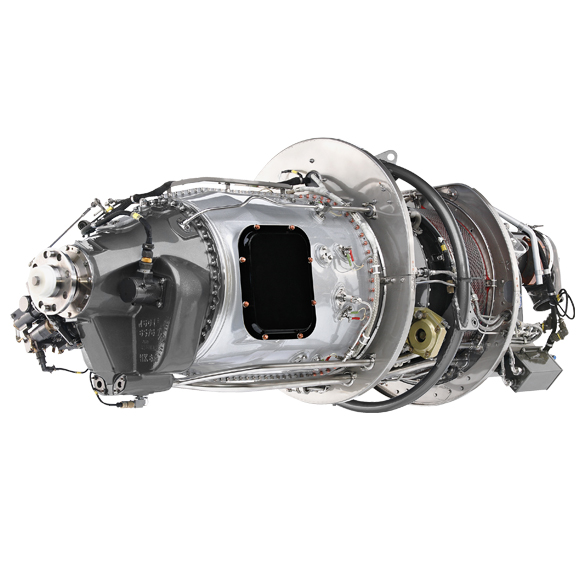

Models H75, H80, H85

GE Aerospace has incorporated sophisticated technologies into the H-Series to advance a legacy of reliable power for turboprop aircraft.

EEPC-enabled engine

A first in turboprops in 2018, GE Aerospace offers enhanced electronic engine and propeller control (EEPC) on its H-Series engines

Aerobatic engine

When the aerobatic H-Series engine is certified, it will be the first electronic and engine propeller controlled (EEPC) aerobatic engine in its class.

H-Series service centers

The H-Series engine’s unique design provides more than just performance. With no fuel nozzles, it requires no hot section inspection and minimal maintenance between overhauls. This means operators can devote more time to their missions in the air. When customers do need assistance, GE Aerospace’s field service and customer support teams are available 24/7 and are backed by a global network of 22 authorized service centers across 12 countries, making repairs local and expedient. GE Aerospace offers two locations for overhaul: Prague, GE Aerospace’s production site, or Prime Turbines, GE Aerospace’s authorized repair and overhaul center in Texas.

Support contacts

+420 222 300 900

+1 877-456-5387

+1 513-552-5387