GEnx Engine

Delivering proven

performance

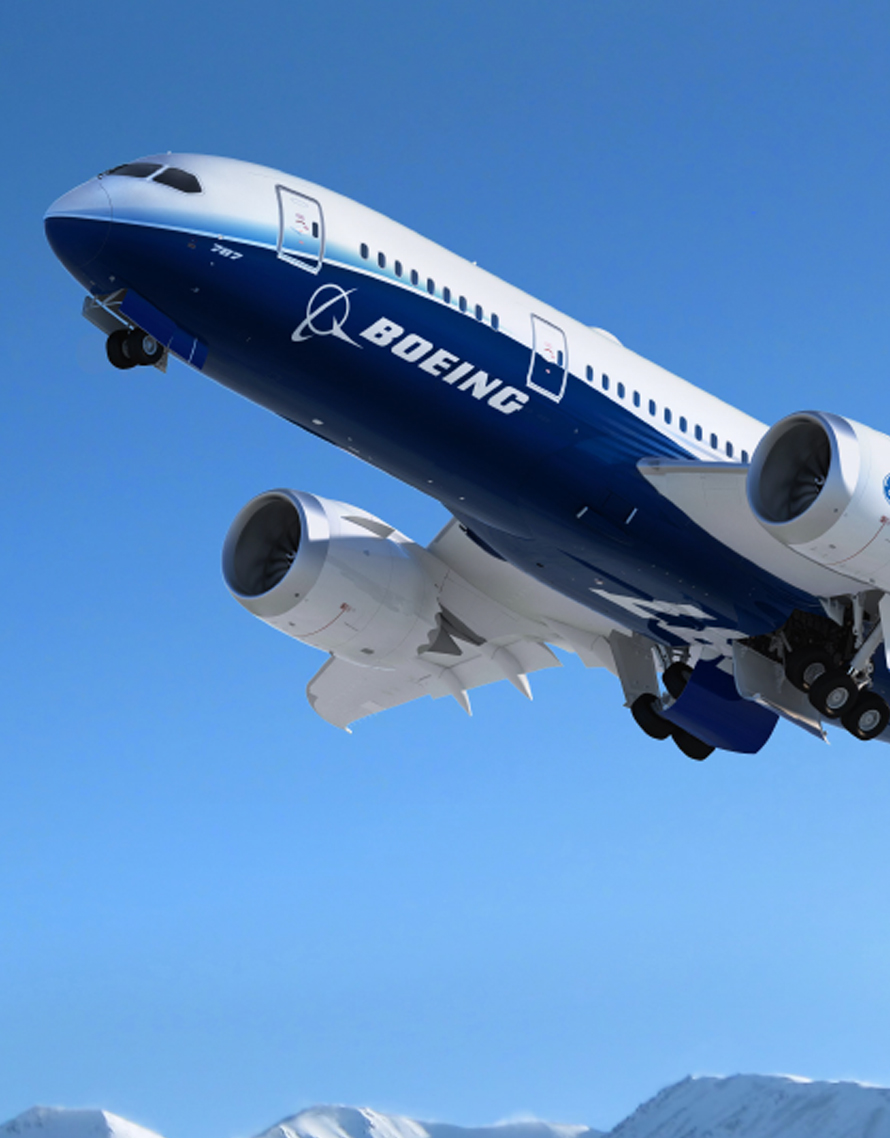

As the fastest-selling widebody jet engine in GE Aerospace history with more than 3,000+ engines in-service and on order, the GEnx delivers proven performance for the Boeing 787 Dreamliner and Boeing 747-8

Leading-edge technologies and advanced architecture offer:

3X

Higher time on wing

Highest reliability

99.98 dispatch rate, 3 times higher time on wing, and 3 times fewer significant events

1.4

%Reduced CO2 emissions per year

Highest reliability

1.4% better SFC vs. the competition for a 3,000 nautical mile mission

3

%Higher annual utilization

Highest availability

3% higher annual utilization means 7 more days per year of aircraft availability

Most

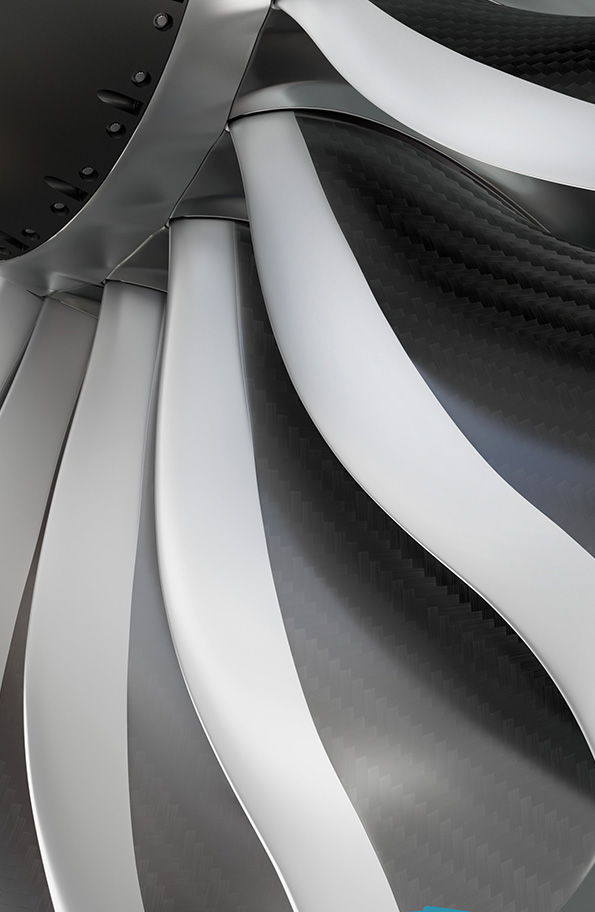

Advanced technology

Advanced materials provide greater durability, lighter weight, and higher LLP lives

The GEnx powers

many of the longest 787 Dreamliner routes

With its superior efficiency, the GEnx powers many of the longest 787 Dreamliner routes, including Qantas’s 787-9 recording-breaking nonstop flight from New York to Sydney.

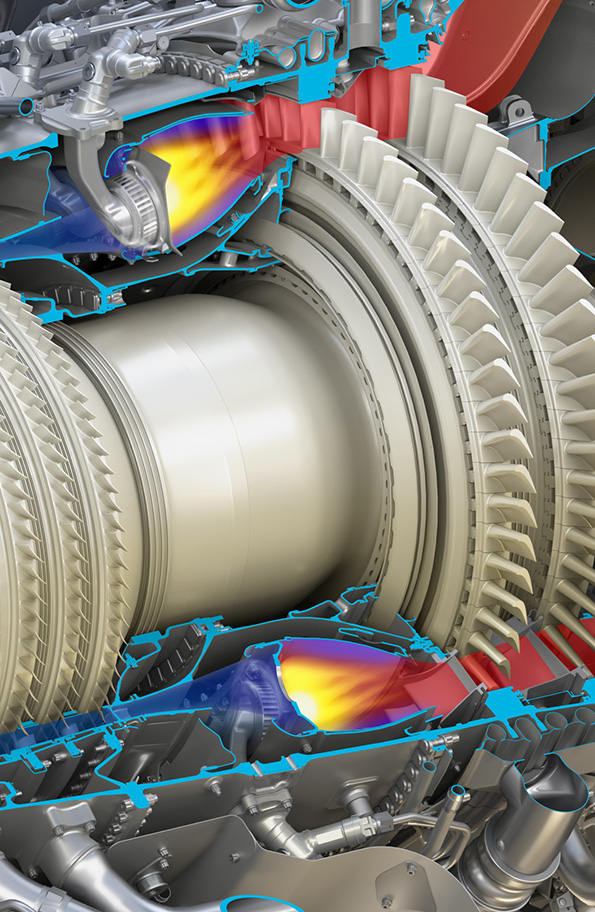

Designed

for Performance

and Reliability

GEnx-1B Engine

Boeing 787, -8, -9, -10

GEnx-2B Engine

Boeing 747-8, Freighter

GEnx Engine Model Comparison

-1B70 (787-8)

-1B74/75 (787-9)

-1B76 (787-10)

-2B67B (747-8)

Take off thrust

69,800

74,100

76,100

66,500

Bypass ratio (takeoff / top-of-climb)

9.0 / 8.3

8.8 / 8.1

8.8 / 7.9

8.0 / 7.4

Overall pressure ratio (takeoff / top-of-climb)

43.8 / 53.3

46.3 / 55.4

47.4 / 58.1

44.7 / 52.4

Air Mass Flow (takeoff, lbs-mass/sec)

2559

2624

2658

2297

Fan Diameter (in)

111.1"

111.1"

111.1"

104.7"

Base Engine Length (in)*

184.7

184.7

184.7

169.7

Compressor Stages (Fan/Booster/HPC)

1/4/10

1/4/10

1/4/10

1/3/10

Turbine Stages (HP/LP)

2/7

2/7

2/7

2/6

Combustor

SAC/TAPS

SAC/TAPS

SAC/TAPS

SAC/TAPS

Control

FADEC III

FADEC III

FADEC III

FADEC III

Bearings

2B+4R

2B+4R

2B+4R

2B+4R