Electrical Power

Improving aircraft

Explore our offerings

Power Generation

Power Conversion

Power Integration

Power Distribution

Power Control

Silicon Carbide

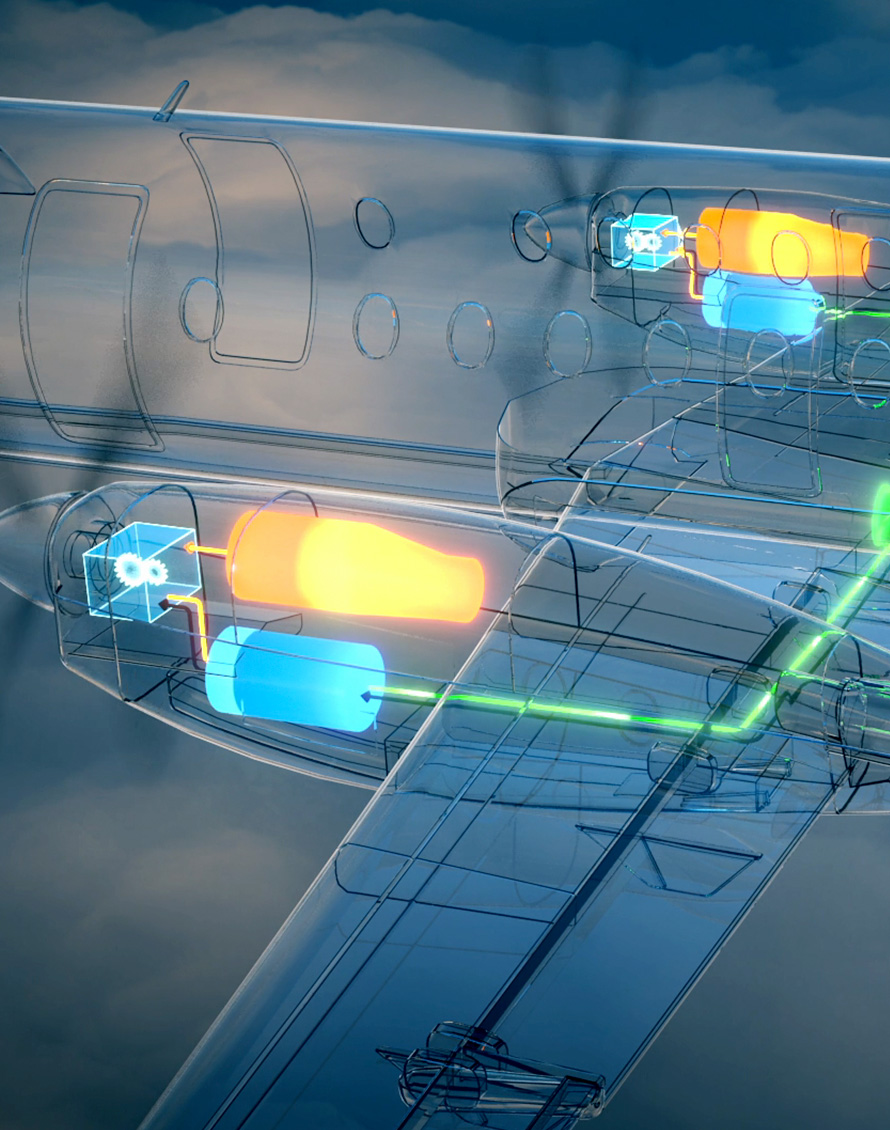

The aviation industry has been moving toward More Electric Aircraft

Using more electricity on aircraft to power loads for thrust /lift creation or next generation military systems creates several challenges. These are around the use of high voltage, thermal efficiency and safety.

GE Aerospace's Electrical Power team is at the forefront of solving these challenges

- Power density to improve platform performance

- Distributed load management to reduce wiring weight and increase useful space

- Safe usage of high voltages to power future propulsion or mission systems

- System configurability that allows efficient platform change implementation

- Tools that permit platform tailoring to individual operator needs, by the manufacturer

- Integration and electrical power system certification expertise to reduce new program execution risk

Electrical power capabilities

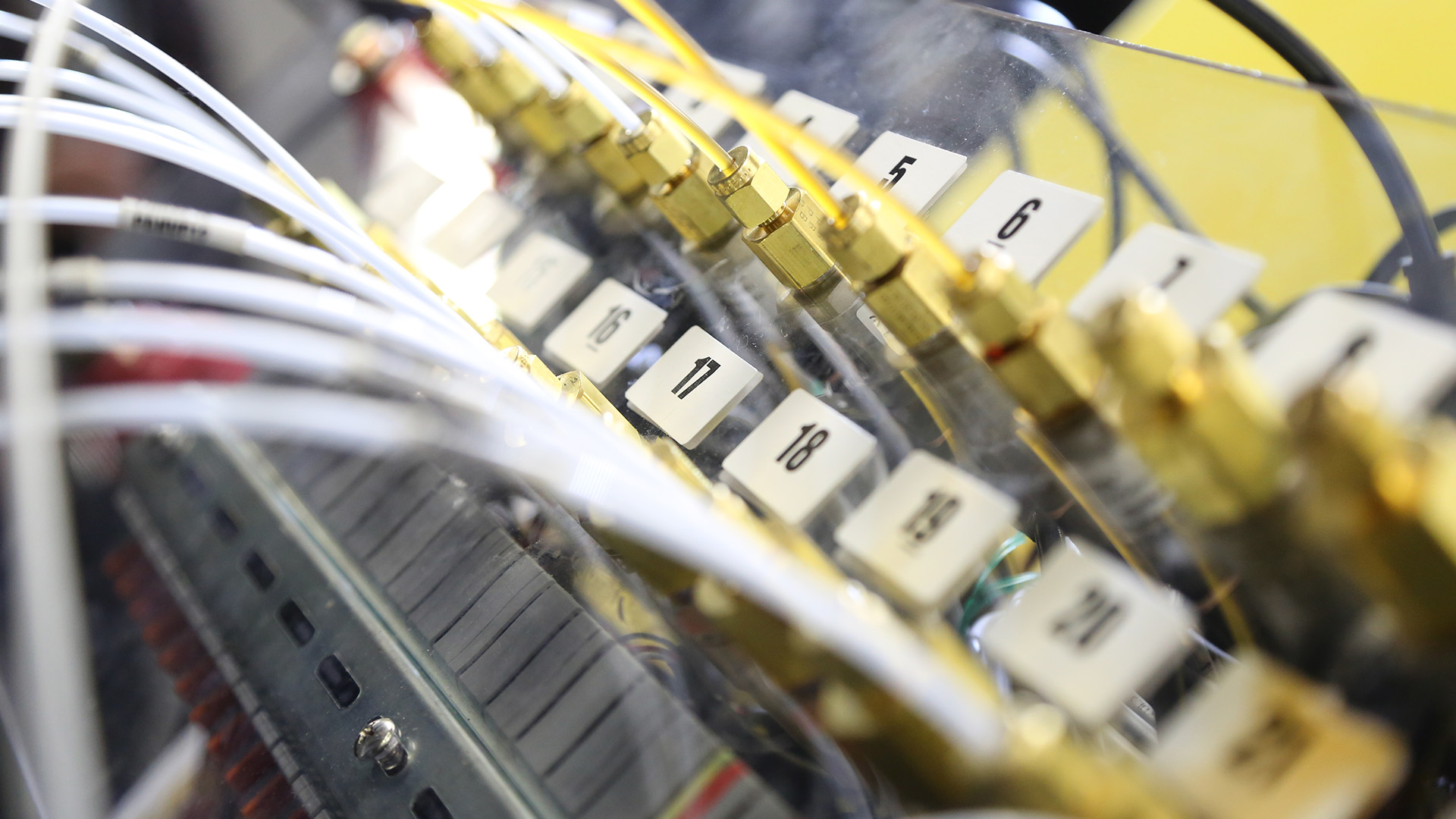

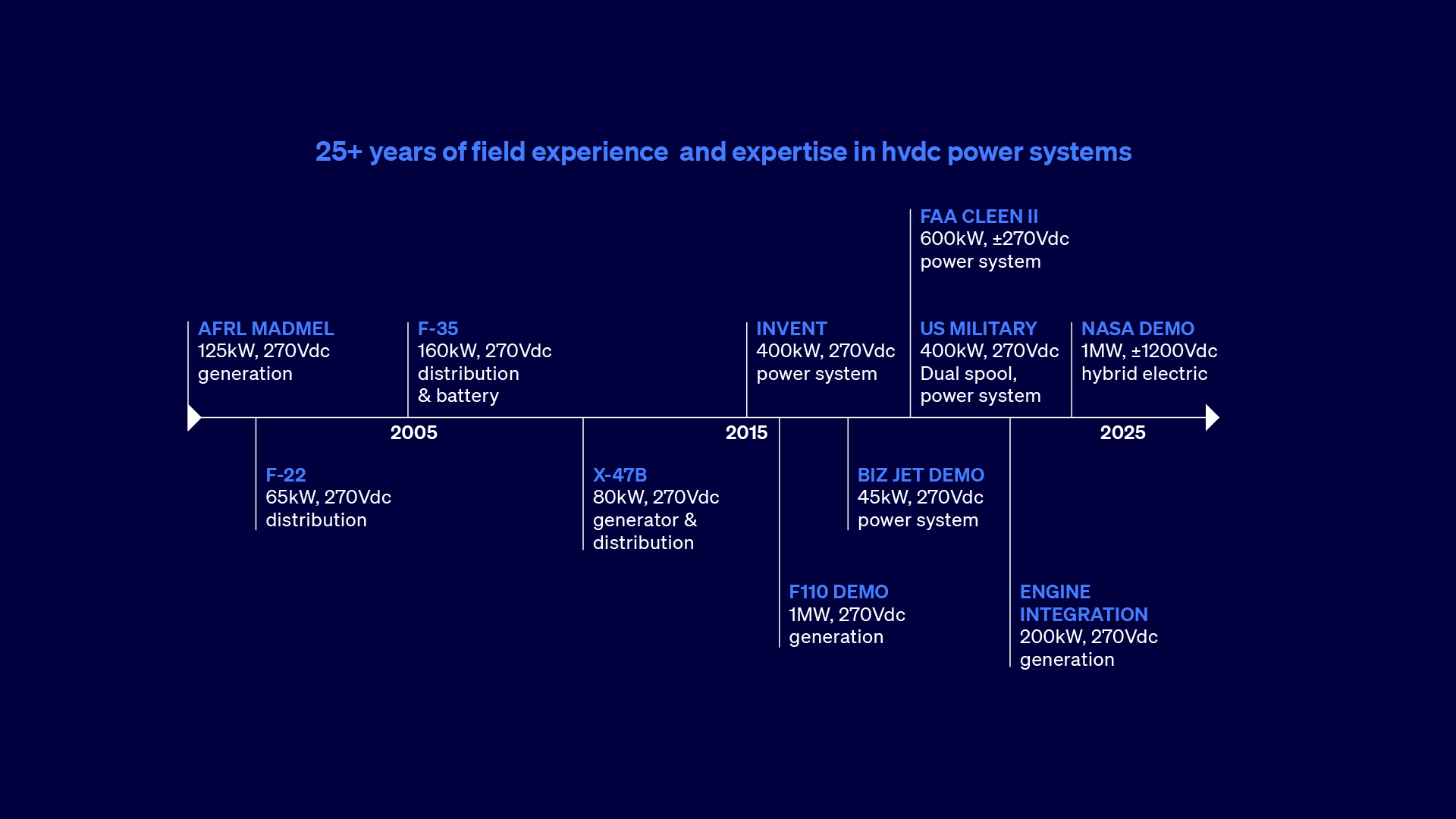

GE Aerospace’s power generation systems have proven performance and reliability in the harshest of environments, with more than 10,000 units delivered around the world.

GE’s power generation systems span a wide range of 115VAC, 230VAC and 270VDC applications including Variable Frequency Generators, Variable Speed Constant Frequency Generators and Starter Generators. We offer integrated systems which mate the control and power electronics with the turbo machine or split systems with a separate Converter / Generator Control Unit.

GE provides both air and oil cooled systems spanning the entire spectrum of main, APU, back up and emergency aircraft generators. Several of our oil cooled generators use GE’s patented dry cavity cooling approach which substantially improves system efficiency and reliability while allowing the option of combining the cooling loops of the engine, gearbox and generator into a single shared oil system.

GE power generation systems lead the industry with respect to inlet cooling temperatures, power density and efficiency. Leveraging key technologies such as silicon carbide, multi-channel extraction and additive manufacturing improves performance and lowers costs.

GE Aerospace's best in class Silicon Carbide solid state power switches, combined with its high-power electrical systems design skills, allows it to create a range of invertor, convertor and power electronics solutions for vehicles across the land, sea and air domains. Its solutions offer compact, temperature tolerant, reliable switching where high voltage and high energy is to be managed in compact vehicle spaces and environments.

The use of high voltage and energy levels on vehicles is a key to driving performance efficiencies and deliver solutions to problems like sustainability and conditioning power for high energy military mission systems.

GE’s advancements in SiC and high-power system designs have caught the attention of the US Army. GE has been working with the U.S. Army's CCDC Ground Vehicle Systems Center (GVSC), formally known as TARDEC, to develop high voltage architectures for ground combat vehicles high-power demands that can meet future requirements in the world’s most challenging environments. Our systems have been extensively tested in the lab and field tested to show that they will meet the challenge. All of this has been possible due to GE’s SiC and design capabilities and through the partnership and funding from GVSC.

Read additional information about GE’s partnership with GVSC

GE Aerospace's best in class Silicon Carbide solid state power switches, combined with its high-power electrical systems design skills, allows it to create a range of invertor, convertor and power electronics solutions for vehicles across the land, sea and air domains. Its solutions offer compact, temperature tolerant, reliable switching where high voltage and high energy is to be managed in compact vehicle spaces and environments.

The use of high voltage and energy levels on vehicles is a key to driving performance efficiencies and deliver solutions to problems like sustainability and conditioning power for high energy military mission systems.

GE’s advancements in SiC and high-power system designs have caught the attention of the US Army. GE has been working with the U.S. Army's CCDC Ground Vehicle Systems Center (GVSC), formally known as TARDEC, to develop high voltage architectures for ground combat vehicles high-power demands that can meet future requirements in the world’s most challenging environments. Our systems have been extensively tested in the lab and field tested to show that they will meet the challenge. All of this has been possible due to GE’s SiC and design capabilities and through the partnership and funding from GVSC.

Read additional information about GE’s partnership with GVSC

GE’s Silicon Carbide (SiC) high efficiency Integrated Starter/Generator Controller (ISGC) is specifically designed for the Next-Generation Combat Vehicle (NHCV). The design utilizes the latest generation of GE’s SiC MOSFETs providing unmatched power levels and durability for the harshest environments.

GE's solutions are also key to enabling the next generation of naval defences and directed energy weapon systems. With our colleagues in GE Power (Marine) our SiC convertors are helping power the USS energy magazines.

GE has been making significant progress in hybrid-electric flight, high power vehicle systems, and electric propulsion systems because of our SiC and system-level expertise. Systems with power capabilities that used to be impossible are now possible, and they also happen to be smaller, lighter, more efficient, and cooler than their Silicon predecessors. SiC MOSFETs and power packaging experience are key components to GE’s success in making these achievements possible for the world.

GE is looking at a future of aviation and hybrid-electric aircraft that might seem far off for some, but not for GE. Our Global Research Center (GRC) in conjunction with GE’s Aviation business is currently developing a SiC-based, lightweight inverter for MW-class power conversion working to NASA-set goals for power density and efficiency under two programs.

This novel inverter will advance the state-of-the-art by leveraging GE’s ultra-high efficiency and high voltage SiC power devices to achieve an industry best power conversion peak efficiency (goal of 99%) and power density (goal of 19kW/kg for the active components)

This SiC-based MW inverter will be ground-tested and represents the first step towards a lightweight flight-worthy inverter to enable hybrid-electric aircraft applications. This technology could revolutionize how we travel in the future.

Electrical Power Integration

- Next generation product creation

- Customer collaboration on electrical power solutions

- Right-first-time delivery to initial platform power-on

- Complete system integration solutions

- Management of ATA 24 certification for customers

- Delivery of complete, qualified end-to-end systems

Complete electrical power and controls solution for civil and military aircraft:

- Starting & generation

- Conversion & control

- Distribution management

- Battery systems

Tier 1 integration - US and UK

- End to end testing across entire electrical power system

- 155,000+ sq ft, two high bays

- Commercial / military separateness

- Six drive cells, ~1000 to 3000 HP

- Expanded load bank farm and switch matrix

- 15 MW of available power

- Capable of testing 6 aircraft EPS simultaneously

- LEED Gold certified

Setting a new standard in power savings

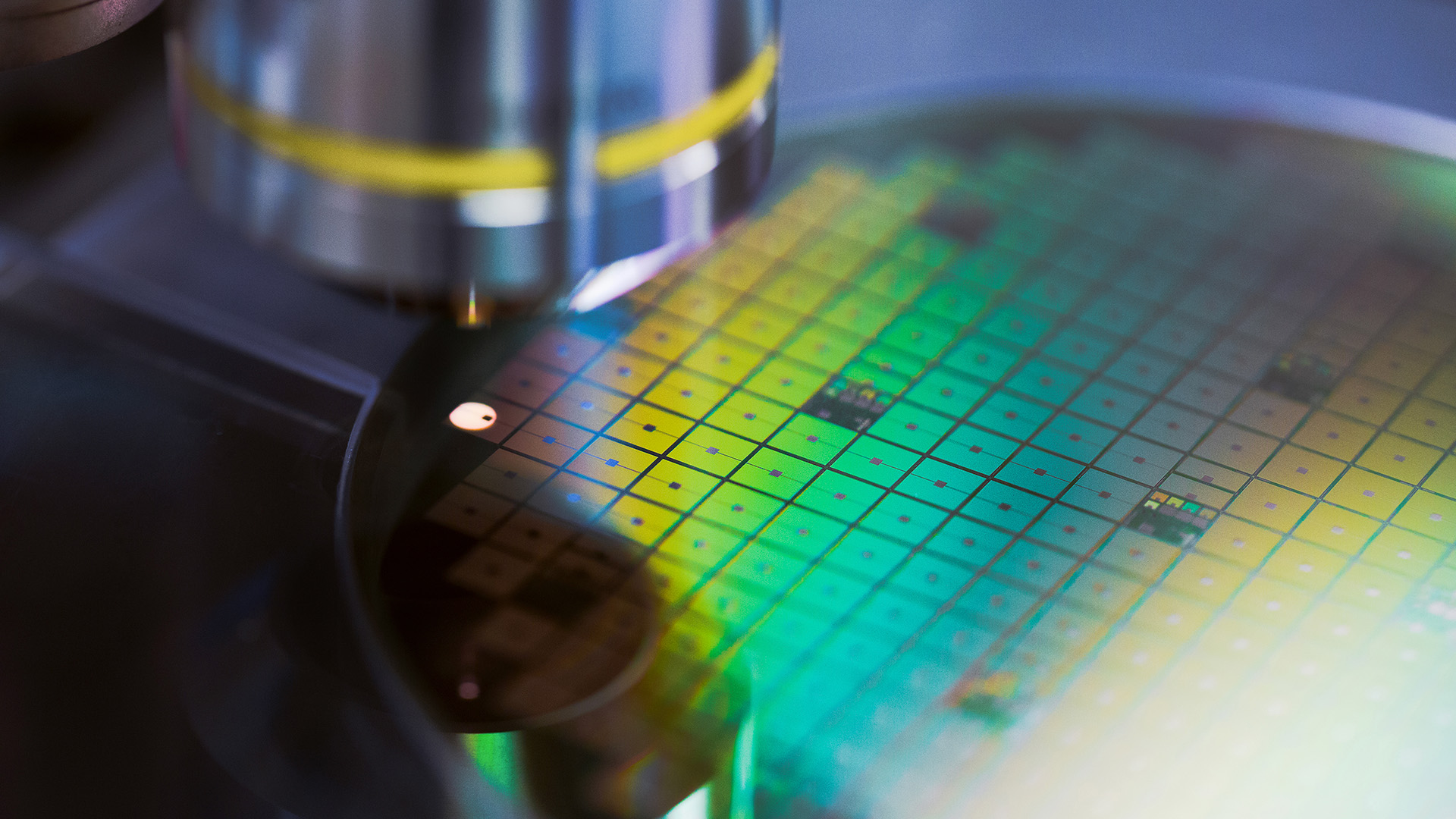

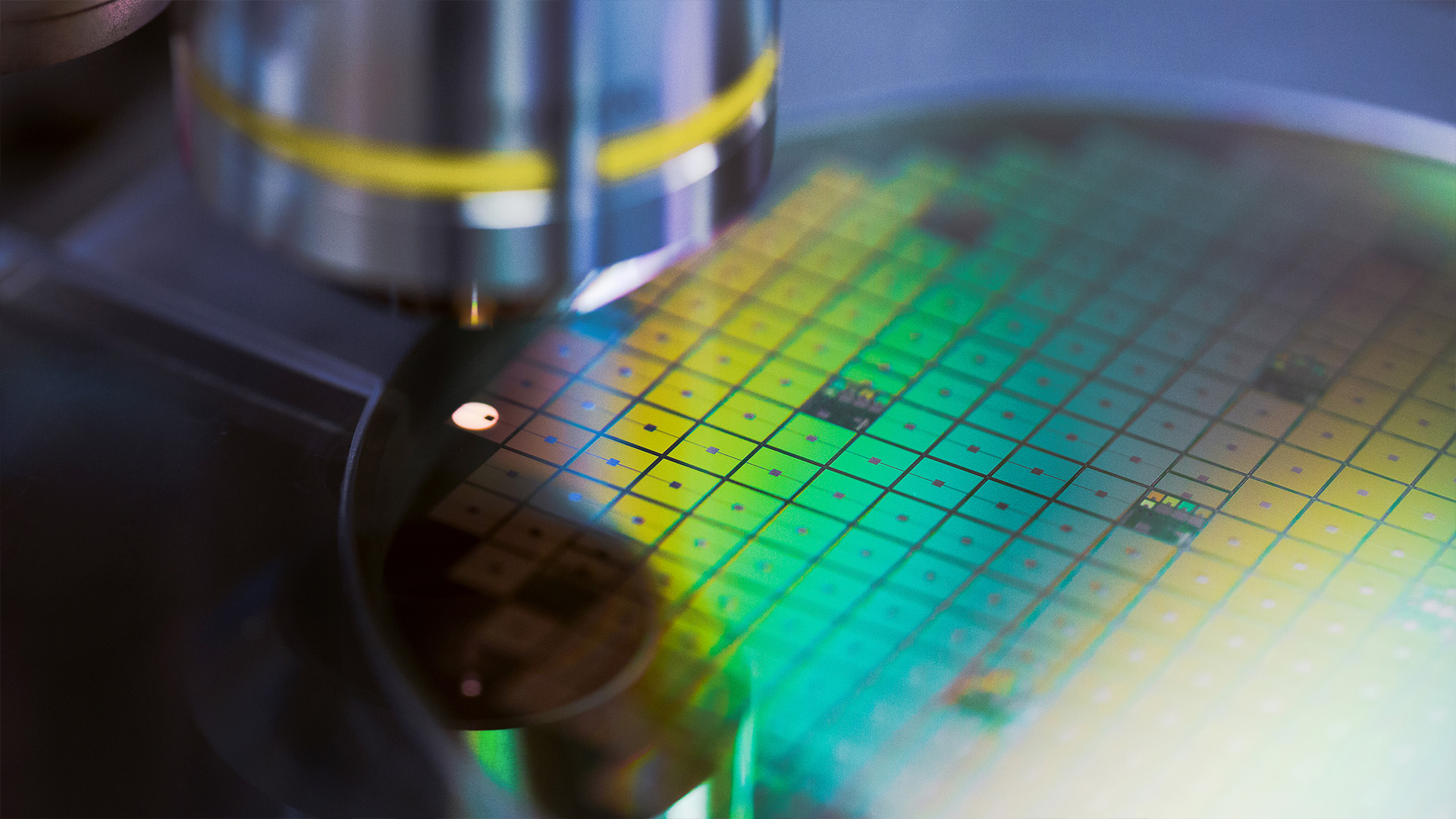

Just as Silicon (Si) became the semiconductor standard 30 years ago SiC is now revolutionizing the electric power industry. It can work at temperatures unreachable by Si chips and can operate at much higher frequencies because these devices are much more efficient. SiC-based devices can also manage the same level of power as Si devices but at half the size and weight.

GE Aerospace SiC advantages

HIGHEST TEMPERATURE TOLERANCE

200°C rated die, reduced cooling system complexity, cost and size

FEWER SWITCHES

Reduced losses, improved size, weight and power capabilities

HIGHER CURRENT DENSITY

2x Power density at same size and weight

HIGHER ENERGY BAND GAP

More robust against heat, radiation and electromagnetic disturbances.

POWER OVERLAY TECHNOLOGY

Ultra-thin profile that enables 40% space savings

2x cooling compared to wire-bonded modules

FUEL SAVINGS

Fuel savings achieved by reducing an aircraft’s weight by 1,000 lbs.

MORE POWER

Increasing more electric vehicle ranges by 10%.

LESS COMPLEXITY

Eliminating complex and heavy cooling systems on

vehicles.

HIGHER POWER LEVELS

Designing systems at power levels not yet attainable with current technology.

SiC technology leader

GE has been a leader in SiC technology development for nearly two decades. From chip design and component engineering to full system implementation, GE has demonstrated class-leading performance in power devices, advanced packaging and power electronics applications. GE offered the Industry’s first -55 to 200˚C MOSFET

-

First SiC photodiode studies for UV, combustion.

-

World's first SiC op amp with high temperature operation.

-

SiC Flame Tracker (UV combustion monitor) enters production. First SiC product.

-

Fully capable 4" SiC fabrication in place, demonstrated MOSFET VTH stable @ 200°C.

-

Gen 1 MOSFET: AEC-Q101 qualified 1.2kV SiC MOSFET with industry-leading performance.

-

ISO9001: 4" fabrication.

-

6" device fabrication and packaging.

-

Gen 3 MOSFET: AEC-Q101 qualified 1.2kV SiC MOSFET, 200°C rated. 1.2kV, 25mΩ.

-

SiC enabled US Army demonstrator for next generation combat vehicles.

-

Aviation industry-first SiC converter with GE SiC.

3x higher reliability

<25% switching losses

4x switching frequency

2x power density

AEC-Q101 qualified

Power and current density

Resistance and inductance

Robustness

Weight

Power density

Power quality

1-5% system efficiency

2x power density

2x reliability

Sustainability on MEA narrow-body

500-1,000 lbs weight

1-3% Fuel Burn

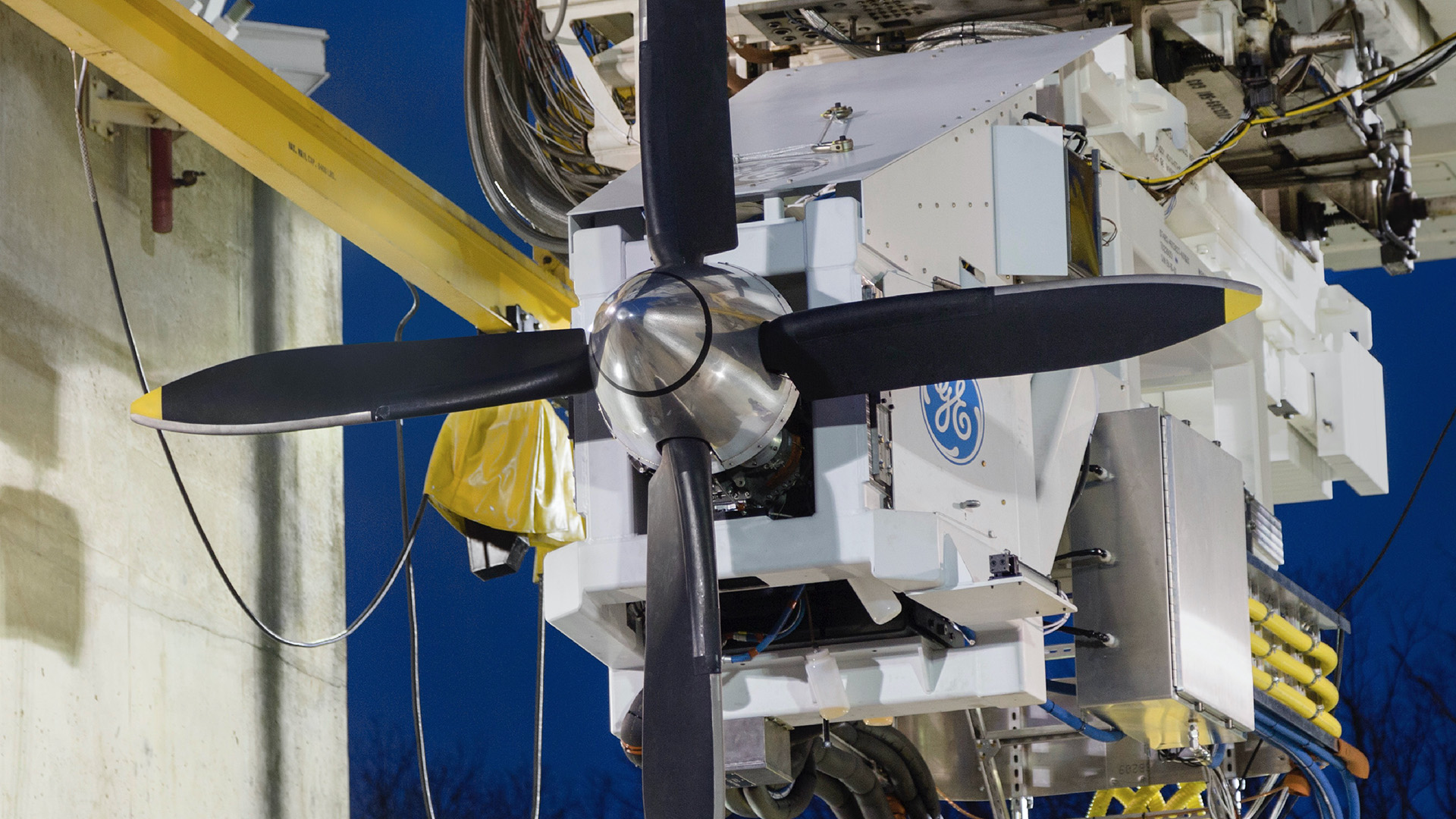

GE has been making significant progress in hybrid-electric flight, high power vehicle systems, and electric propulsion systems because of our SiC and system-level expertise. Systems with power capabilities that used to be impossible are now possible, and they also happen to be smaller, lighter, more efficient, and cooler than their Silicon predecessors. SiC MOSFETs and power packaging experience are key components to GE’s success in making these achievements possible for the world.

GE is looking at a future of aviation and hybrid-electric aircraft that might seem far off for some, but not for GE. Our Global Research Center (GRC) in conjunction with GE’s Aviation business is currently developing a SiC-based, lightweight inverter for MW-class power conversion working to NASA-set goals for power density and efficiency under two programs.

This novel inverter will advance the state-of-the-art by leveraging GE’s ultra-high efficiency and high voltage SiC power devices to achieve an industry best power conversion peak efficiency (goal of 99%) and power density (goal of 19kW/kg for the active components).

This SiC-based MW inverter will be ground-tested and represents the first step towards a lightweight flight-worthy inverter to enable hybrid-electric aircraft applications. This technology could revolutionize how we travel in the future.

With the vehicles moving towards reduced emissions and reduced cost of ownership, heavy industrial vehicles used in construction, mining, and agriculture applications must evolve. Silicon Carbide (SiC) is an enabler that will allow vehicles to achieve unmatched efficiencies with electrification.

GE’s SiC power modules can operate in the harsh environments common for industrial vehicles with unprecedented reliability. With SiC devices certified to automotive AEC-Q101 standards, GE SiC modules can yield:

- 2x reduction in size and weight compared to IGBT systems, simplifying integration, in a package 40% smaller than competing modules

- Increased fuel efficiency, reducing emissions

- Less maintenance and reduced downtime due to simplified systems, reducing cost of ownership

Just as in our military ground vehicle applications, GE’s proprietary technology allows for scalability and customization to meet the intense needs of industrial vehicles

| Module type | Voltage rating (V) | Current/ switch (A) | Max junction temp | Size W x L x H |

|

|---|---|---|---|---|---|

|

Full Bridge Rectifier | 650 | 200 | 175°C | 69 x 103 x 16 mm |

| Center Tap Rectifier | 650 | 400 | |||

| Dual | 1200 | 475 | 175°C | 48 x 86 x 18 mm | |

| 1700 | 425 | ||||

| 1/2 bridge | 1200 | 475 | 175°C | 48 x 86 x 18 mm | |

| 1700 | 425 | ||||

| 1/2 bridge | 1200 | 875 | 175°C | 100 x 140 x 38 mm | |

| 1700 | 765 | ||||

|

1/2 bridge | 1200 | 1425 | 175°C | 90 x 134 x 41 mm |

| 1700 | 1400 | ||||

|

6 switch | 1200 | 6 x 475 | 175°C | 90 x 134 x 37 mm |

| 1700 | 6 x 425 | ||||

| 6 pack (3 phase) |

1200 | 3 x 475 | 175°C | 90 x 134 x 30 mm | |

| 1700 | 3 x 425 |