TrueChoice™

Material

It's all about

choice

With TrueChoice™ Material, high quality OEM new and used parts, advanced repairs, and technology upgrades for airlines and MROs are in our DNA. It’s all part of our commitment to offering more material options to enhance engine performance and reduce your cost of operations.

With GE Aerospace parts, you’re assured world-class quality and comprehensive product support

New Parts: Since the part design process begins with us, we understand how each part within a complex engine system interacts with the others. This expertise, combined with our drive to continually upgrade product durability and improve processes, helps reduce your cost of engine ownership. This is demonstrated through fleet-wide improved time on wing and is coupled with reductions in delays, cancellations, aborted takeoffs, and in-flight shutdowns.

With 500,000 square feet of warehouse and distribution operations managing 70,000 parts at any given time, GE Aerospace offers a robust parts inventory stream with material that is system-tested and certified, supported, and ready when you need it for all your material needs.

With 500,000 square feet of warehouse and distribution operations managing 70,000 parts at any given time, GE Aerospace offers a robust parts inventory stream with material that is system-tested and certified, supported, and ready when you need it for all your material needs.

Reducing your overall cost of ownership

Used Parts: GE Aerospace's used serviceable parts are cost-effective complements to new parts to help lower shop visit cost. And because we provide only traceable parts and OEM-approved repairs, you can purchase material with the confidence that your engine contains parts tested and certified as an engine system, reducing unknowns, and ensuring a fully supportable configuration.

In addition, our used parts are offered as stand-alone products or as part of the TrueChoice™ portfolio of offerings to support cost of ownership throughout a fleet’s life.

In addition, our used parts are offered as stand-alone products or as part of the TrueChoice™ portfolio of offerings to support cost of ownership throughout a fleet’s life.

With 13,000+ repairs introduced, no one in the industry offers more

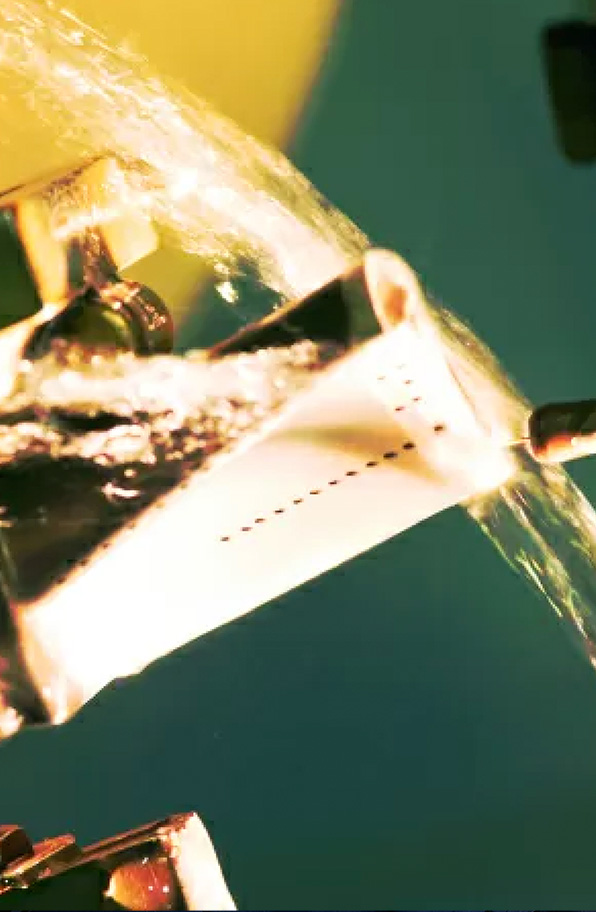

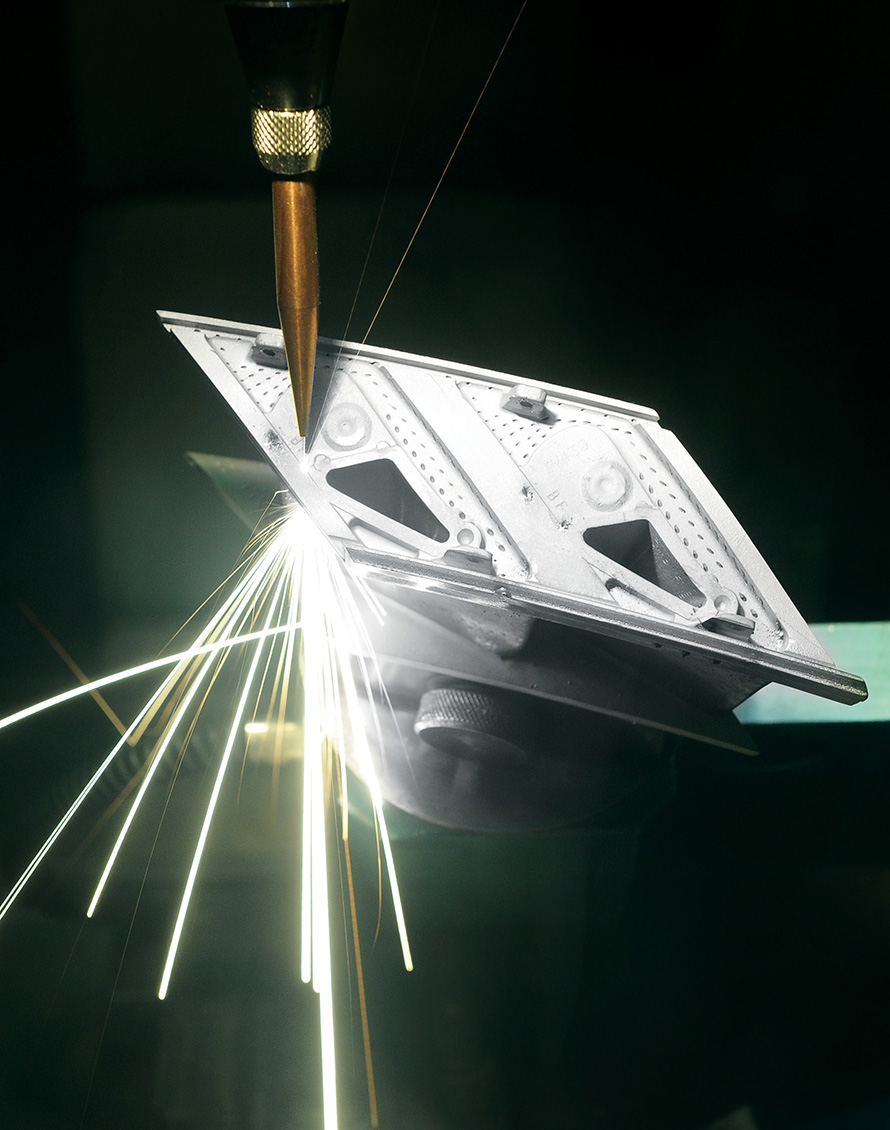

Repair: GE Aerospace’s advanced repairs make more of your engine parts serviceable, providing you with significant shop visit savings. Advanced repairs enable your business to reclaim parts that would otherwise have to be replaced. Repairs that restore these parts to within serviceable limits can help to maintain and extend an engine’s service life – and positively affect your bottom line while lowering your maintenance cost.

We focus this technology development on advancements which restore engine performance, durability and reliability to strict technology standards, generating savings across your engines’ lifespan, and enhancing engine and parts re-marketability. In addition, we back our repair workmanship with industry-leading warranties.

We focus this technology development on advancements which restore engine performance, durability and reliability to strict technology standards, generating savings across your engines’ lifespan, and enhancing engine and parts re-marketability. In addition, we back our repair workmanship with industry-leading warranties.

Services and Specialties

Repair facilities/capabilities

GE Aerospace dedicated repair facilities

Singapore Plant 62

Singapore Plant 23

Cincinnati Ohio, USA

Hungary

McAllen Texas, USA

Parts

• Joining complex alloys

• Laser weld

• Laser weld

• HPT airfoils

• LPT blades

• Combustors

• Turbine Center Frames

• LPT blades

• Combustors

• Turbine Center Frames

• Rotating parts

• Frames, cases

• Combustors

• Fan blades

• Frames, cases

• Combustors

• Fan blades

• LPT shrouds

• Seals

• Fan hardware

• Composite fan blades

• Seals

• Fan hardware

• Composite fan blades

• LPT nozzles

• HPT hangers

• HPT nozzles

• HPT hangers

• HPT nozzles

Core capabilities

• 3D surface measurement

• Automated welding

• Coatings HVOF

• Brazing

• Robotic blending

• Peening

• Heat Treatment

• Joining complex alloys

• Laser weld

• Automated welding

• Coatings HVOF

• Brazing

• Robotic blending

• Peening

• Heat Treatment

• Joining complex alloys

• Laser weld

• FPI, EC, X ray, U/T, CT, 3D surface measurement

• Cleaning: chemical, waterjet, FIC

• Welding/brazing

• EB welding

• EDM/grinding

• Laser additive

• Laser multi hole manufacturing

• Coatings

• Peening

• Heat Treatment

• Cleaning: chemical, waterjet, FIC

• Welding/brazing

• EB welding

• EDM/grinding

• Laser additive

• Laser multi hole manufacturing

• Coatings

• Peening

• Heat Treatment

• Cleaning: Chemical, waterjet, ultrasonic

• Inspection: X ray, FPI, U/T, EC, robotic , 3D surface measurement

• Machining/ grinding/peening

• Welding/brazing

• EB welding

• Laser multi hole manufacturing

• Additive Cold Metal

• Transfer Welding

• 3D polymer printing

• Heat Treatment

• Coatings

• Inspection: X ray, FPI, U/T, EC, robotic , 3D surface measurement

• Machining/ grinding/peening

• Welding/brazing

• EB welding

• Laser multi hole manufacturing

• Additive Cold Metal

• Transfer Welding

• 3D polymer printing

• Heat Treatment

• Coatings

• Cleaning

• 3D surface measurement

• Brazing

• Welding

• Machining

• EDM

• Composite processes

• Clean Room

• Autoclave

• Heat Treatment

• Coatings

• 3D surface measurement

• Brazing

• Welding

• Machining

• EDM

• Composite processes

• Clean Room

• Autoclave

• Heat Treatment

• Coatings

• X ray

• 3D surface measurement

• Cleaning, FIC

• Welding

• Brazing

• Grinding

• EDM

• VPA/ PtAl coatings

• Heat Treatment

• 3D surface measurement

• Cleaning, FIC

• Welding

• Brazing

• Grinding

• EDM

• VPA/ PtAl coatings

• Heat Treatment

Repair warranty program

Repairs are guaranteed for workmanship for 4,000 engine flight hours (up from the original 2,000) or 2,000 part cycles or 24 months following redelivery, whichever occurs first for CFM56-3/5A/5B/7B/5C engines.

For CF6-80C/80E engines, the coverage has been tripled to 6,000 engine flight hours or 1,500 part cycles or 24 months following redelivery, whichever occurs first. For CF34-8/10 engines, the coverage is 3,000 engine flight hours or 2,300 part cycles or 18 months following redelivery, whichever occurs first.

ENGINE MODELS

Past Time (hours, months)

Part Cycles

Redelivery (months)

CFM56-3/5A/5B/7B/5C

4000, 24

2000

24

CF6-80C/80E

6000, 24

1500

24

CF34-8/10

3000, 18

2300

18

Other

2000, 12

1000

12

Enhancing engine performance, while reducing your operational costs

Technology Upgrades: GE Aerospace offers engine upgrades to enhance performance and reduce cost. Our engine upgrade kits incorporate today’s technologies to reduce the cost of ownership of the upgraded engines, and the aircraft they power.

Using a platform approach combined with evaluation and cost-benefit analysis, we look for opportunities to infuse the technologies of current production engines into mid-life and mature engines, lowering fuel burn and increasing time on wing, reliability, repairability and residual value, as well as providing adherence to more stringent environmental regulations. For more comprehensive programs, that include new and used parts and repairs, contact your sales director.

Using a platform approach combined with evaluation and cost-benefit analysis, we look for opportunities to infuse the technologies of current production engines into mid-life and mature engines, lowering fuel burn and increasing time on wing, reliability, repairability and residual value, as well as providing adherence to more stringent environmental regulations. For more comprehensive programs, that include new and used parts and repairs, contact your sales director.

Continuous technology evolution throughout the engine lifecycle

We continue to demonstrate a legacy of implementing these ongoing technology improvements throughout the engine lifecycle. These enhancements result in increased fuel efficiency, improved reliability, extended time-on-wing, and supports our commitment to a more sustainable future.