XA100

Adaptive Cycle Engine

Outperform. Outpace.

Only XA100.

A new era of combat propulsion is here. The XA100 adaptive cycle engine — designed, built, and tested through the U.S. Air Force's Adaptive Engine Transition Program (AETP) — defines a revolutionary jump in propulsion capabilities this decade that address the challenges faced from increasing geopolitical threats.

Revolutionary capabilities to deter geopolitical threats

We can exchange engines with a full quick engine change (QEC) swap. On Wing Support will then service your engine at one of our quick-turn shops that can repair or replace the fan, compressor, combustor, and high-pressure turbine and low-pressure turbine modules. GE’s On Wing Support will coordinate the repair of modules to ensure the engine is repaired quickly and reliably. On Wing Support is an authorized provider for engine service bulletins and warranty programs for GE Aerospace, CFM56, and LEAP engines.

Ready to meet warfighter needs

30

%More range

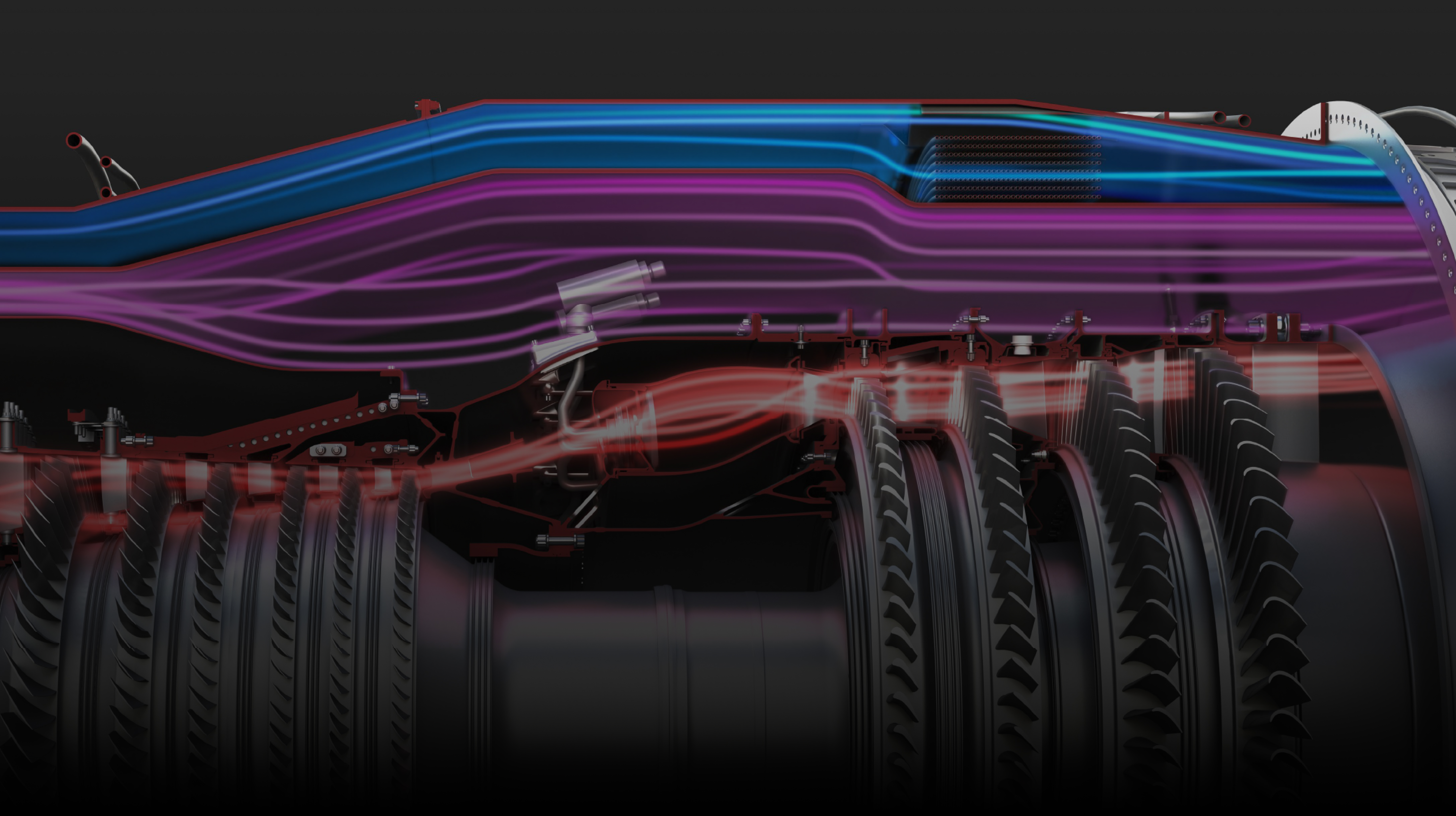

Adaptive engine

The adaptive cycle engine provides a high-thrust mode for maximum power and a high-efficiency mode to extend mission range. Automatically alternating between these modes dramatically transforms mission capability and enables unrestricted operations.

2

%Thermal management

Third stream advantage

This advanced capability provides an extra source of cooled air to improve propulsion and fuel efficiency. Most importantly, it enables a step change in power and thermal management capability that will be required for next-generation mission systems.

>

20

%More acceleration

Advanced materials and components

The use of new, lighter-weight and more durable materials along with advanced additive manufacturing methods allows the engine to operate beyond previous-generation engine limits for more survivability. These new materials and methods also improve reliability and serviceability of the engine.

Congress renews support

for adaptive engine technology

"We appreciate the Senate Appropriations Committee decision to provide funds for next-generation propulsion programs, which will help provide our military pilots with cutting-edge capabilities needed in the face of today’s growing geopolitical threats. For over 100 years, GE Aerospace has helped ensure U.S. military aviation superiority, and with support in both the Senate and House, our XA100 engine stands ready to continue that legacy for decades to come."

Latest news and updates

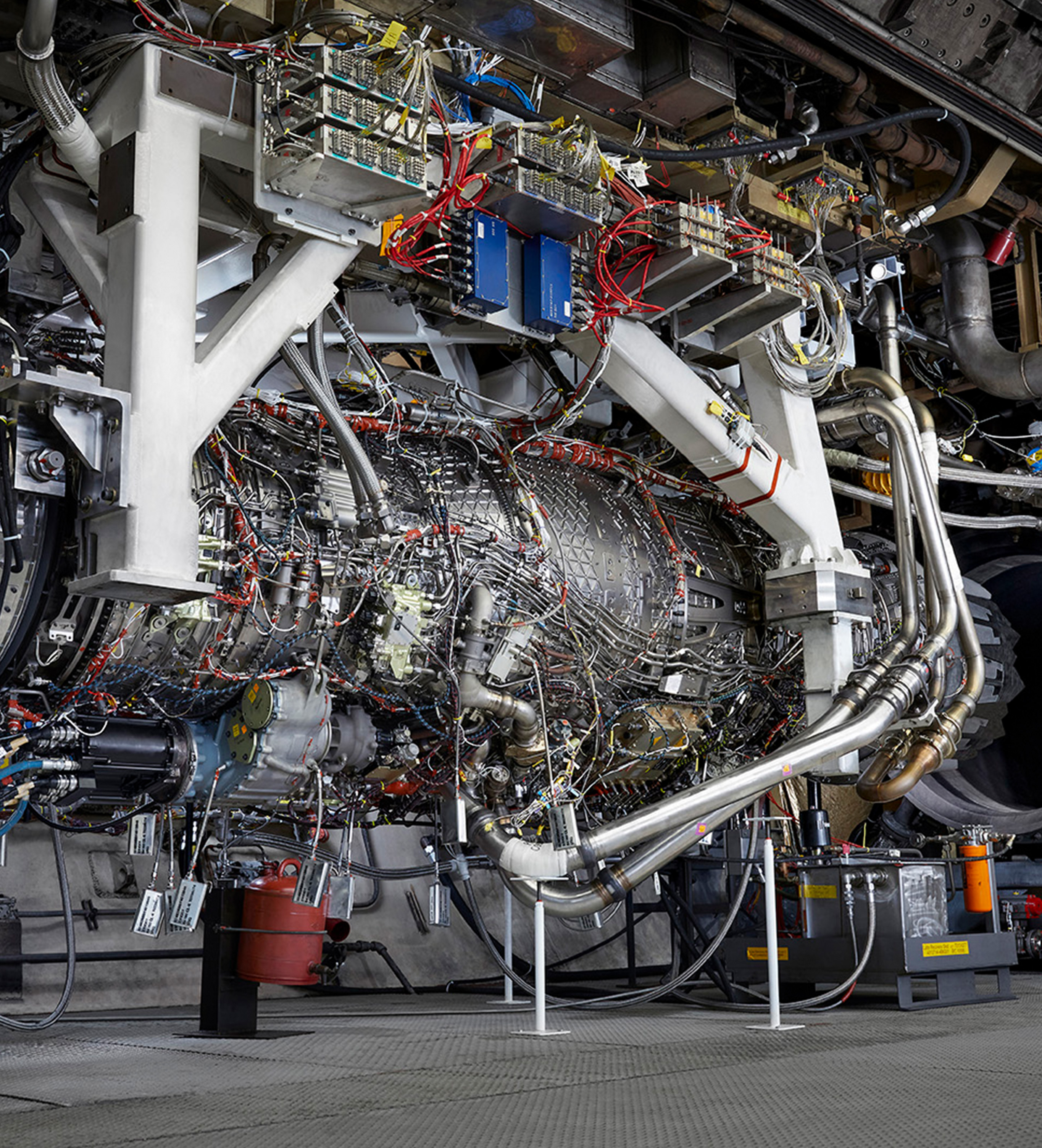

The XA100 is fully tested and ready to provide revolutionary propulsion capabilities for the F-35, with two engines and having completed the Air Force testing process.

Watch video

Amy Gowder, president and CEO of GE Aerospace Defense and Systems business, discusses the history and future outlook of GE Aerospace's mission to revolutionize military flight through innovative technologies like the XA100.

Watch video

GE Aerospace has successfully concluded testing on its second XA100 adaptive cycle engine with the U.S. Air Force at the Arnold Engineering Development Complex (AEDC).

Read More

GE Aerospace's David Tweedie explains why only the XA100 can deliver the revolutionary capabilities our military needs by 2028.

Read More

The U.S. Air Force and GE Aerospace initiated Phase 2 testing of GE’s second XA100 adaptive cycle engine, marking the first test of an Adaptive Engine Transition Program (AETP) at the Arnold Engineering Development Complex.

Read more

The XA100 Adaptive Cycle Engine is ushering in a new era of combat propulsion to deliver transformational capability to fighter aircraft and the U.S. military.

WATCH VIDEO

GE Aerospace has concluded phase 1 testing on its second XA100 adaptive cycle engine as part of the U.S. Air Force’s Adaptive Engine Transition Program (AETP) at GE’s Evendale, Ohio altitude test facility.

Read more

GE Aerospace initiated testing on its second XA100 adaptive cycle engine, its final planned prototype engine as part of AETP, at GE’s Evendale, Ohio altitude test facility.

Read more

GE Aerospace’s first XA100 adaptive cycle engine successfully concluded testing, validating the ability of the engine to deliver transformational propulsion capability to fighter aircraft.

Read more

GE Aerospace's Dave Tweedie discusses benefits of the Adaptive Engine Transition Program (AETP), allowing more power and efficiency for future combat aircraft.

Watch video

In February 2019, GE Aerospace's XA100 successfully completed the detailed design process, paving the way for fabricating and testing multiple full-sized adaptive cycle engines.

Read more

The revolutionary Adaptive Cycle Engine from GE Aerospace is the latest in a proud legacy of game-changing propulsion innovations.

Watch video

The XA100 is a product of GE's Edison Works, a team dedicated to the research, development, and production of advanced military solutions. This team has full responsibility for strategy, innovation, and execution of advanced programs. The appearance of U.S. Department of Defense (DoD) visual information does not imply or constitute DoD endorsement.